Glass Bottle Condiment Production Line

- Size:

- 1600x1400x1900mm

- Weight:

- 1600kg

- Type:

- FILLING MACHINE

- Voltage:

- 220v,380v, or base on customer's requirements

- Driven Type:

- Electric

- Automatic Grade:

- Automatic

- Film material:

- milk, WATER, oil, juice

Quality requirement of the project

- Meet customer's quality requirements, to achieve the leading level in the industry

- The corresponding standards of quality acceptance criteria of national standards and tender regulations. The main materials and equipment are health approvals or compliance with the inspection report. Meet the standard Non-gas liquid filling2005(QB/T 2747-2005)

- The final technical parameters of the contract shall prevail.

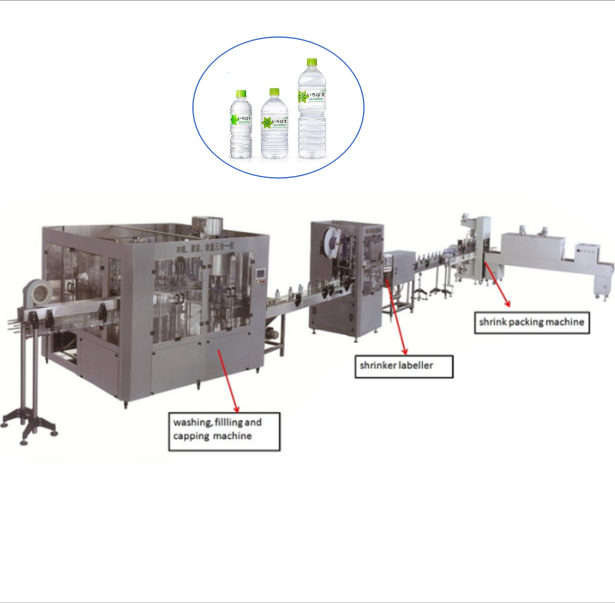

Process Flow

Loading bottles onto the conveyor line (by hand)----filling

machine----capping machine----labeling machine----inkjet

printer----packaging platform (by hand)

Performance:

- This machine is mainly used to automatically wash glass bottles and PET bottles.

- Rinsing nozzles are inserted automatically into bottles, so that water can be spray into the bottoms of bottles.

- External washing device uses a pump to spray water on the outside of bottles.

- The sterile compressed air is blew into bottles to remove the water left in washing processes.

- This machine works with a circulated water tank and pressure pumps. It can wash bottles effectively with less water usage.

- The cold water, hot water, recycling water or alternating hot and cold water can be used to wash bottles.