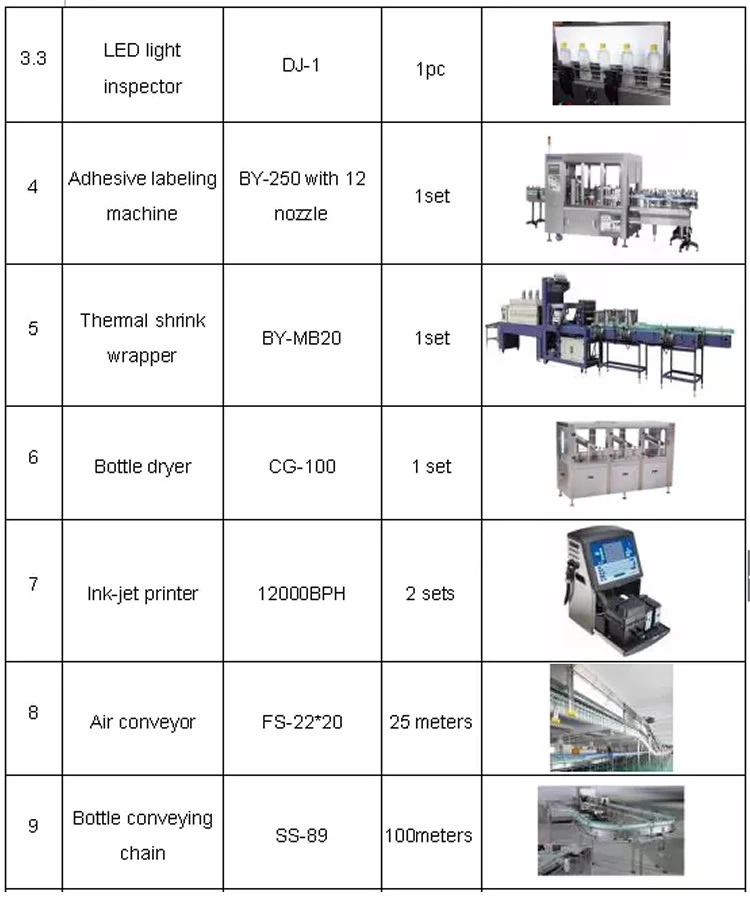

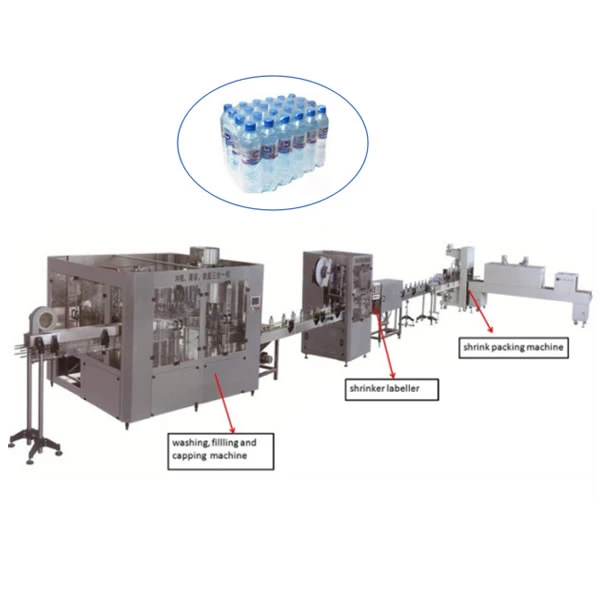

12000BPH 15000BHP 18000BHP 20000BHP 24000BHP Bottled Water Production Line

- Material:

- SUS304

- Capacity:

- 180000bph

- Weight:

- 2000KG

- Function:

- Manufacturing beverage

- Type:

- FILLING MACHINE

- Advantages:

- Enery saving, easy to operate, famous brand PLC/motor

- Voltage:

- 220V/380V

- Driven Type:

- mechanical

- Bottle type:

- Bottle/Customized

- Automatic Grade:

- Automatic

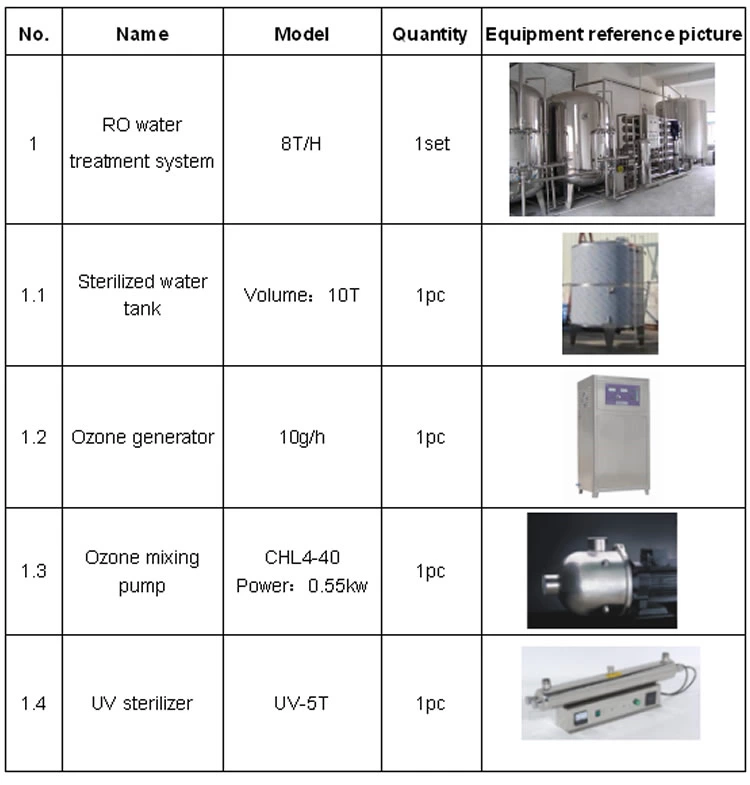

Water treatment equipment description

- The pretreatment system: this system is equipped with RO water pretreatment device, small particles, bring filter raw water suspension colloid, free chlorine, low molecular organic halides (THM, three), thereby significantly reducing turbidity (NTU), the SDI (water pollution index), reduce the odor and color water the water quality to meet the requirements of water film work. At the same time, the security filter to intercept removal of more than 5 mu or more particles, preventing membrane clogging and damage.

- RO reverse osmosis system: reverse osmosis system using the Dow company production of polyamide composite membrane elements in the world's most advanced (TFC film) as the main component, the single membrane desalination rate is more than 99.5%, 97-99% desalination rate, suspended particles, and can effectively remove the organic silicone gel. Matter, bacteria, virus, pyrogen and other impurities, product brand name - Nanfang pump manufacturing Chinese stainless steel high pressure pump, stable and reliable performance, low noise.

- Water supply system: the Guangzhou Jiahuan ozone series, used to kill bacteria in the water tank, and the water of oxygen. The long-term preservation, stainless steel ozone mixing tower deep water aeration mixing of ozone and pure water, the water pump selection system China famous brand: Nanfang pump, system and control device, structure for vertical cylindrical. The built-in 0.2 M titanium filter for removal of bacterial debris, to ensure high purity water water inside the pipe.

- Cleaning system: in the normal operation after a period of time, the reverse osmosis membrane element will be suspended in the water may exist or insoluble salt pollution, it is equipped with chemical cleaning system

- Control system: Japanese MITSUBISHI PLC (MMI) automatic control, electrical components by the French Schneider brand, once the boot device will enter the automatic operation system, which is under the automatic protection operation. Automatic operation, according to the water level automatic shutdown. The reverse osmosis system with multiple protection function and automatic flushing procedure, no the need for manual operation of the whole system, guarantee system of water supply 24 hours a day.

Equipment conditions and other instructions

- Raw water quality: local municipal tap water or general ground water;

- Water quality:Inlet TDS:≤1000ppm Produced water TDS:≤30ppm;

- Capacity:8m³/h(25℃),meet customer requirements;

- It runs more than 350 days a year;

- Power:220/380V/50Hz;

- Total power:17.0kw,Power for operation:12.8KW;

- Overall dimensions(L*W*H):1600*200*500CM;installation area:40 square meter

How to choose bottled water/ beverage production line equipment?

1. Equipment process selection

There are different processes for manufacturing bottled water and beverage products. It is mainly considered from the following aspects:

(1) Pre-treatment: such as water treatment equipment, choose secondary reverse osmosis, nanofiltration, brackish water equipment or microfiltration? Before deploying equipment, choose high temperature sterilization or medium temperature filling? Choose one from plate type, tube type, inverted bottle, spray, water bath, sterilization kettle, or a combination of multiple uses?

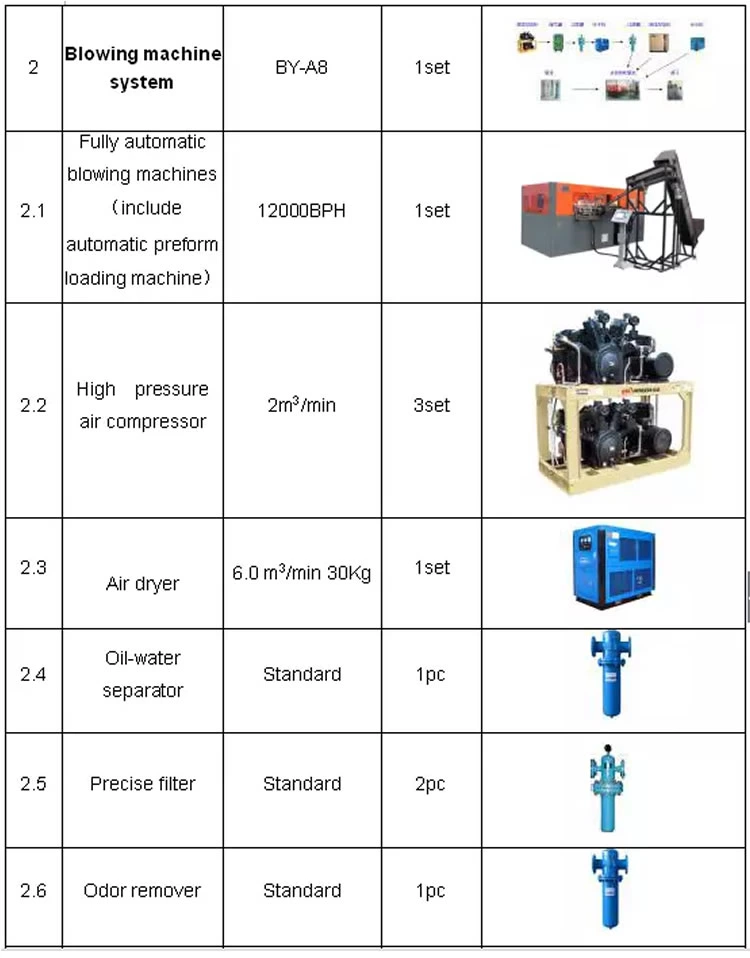

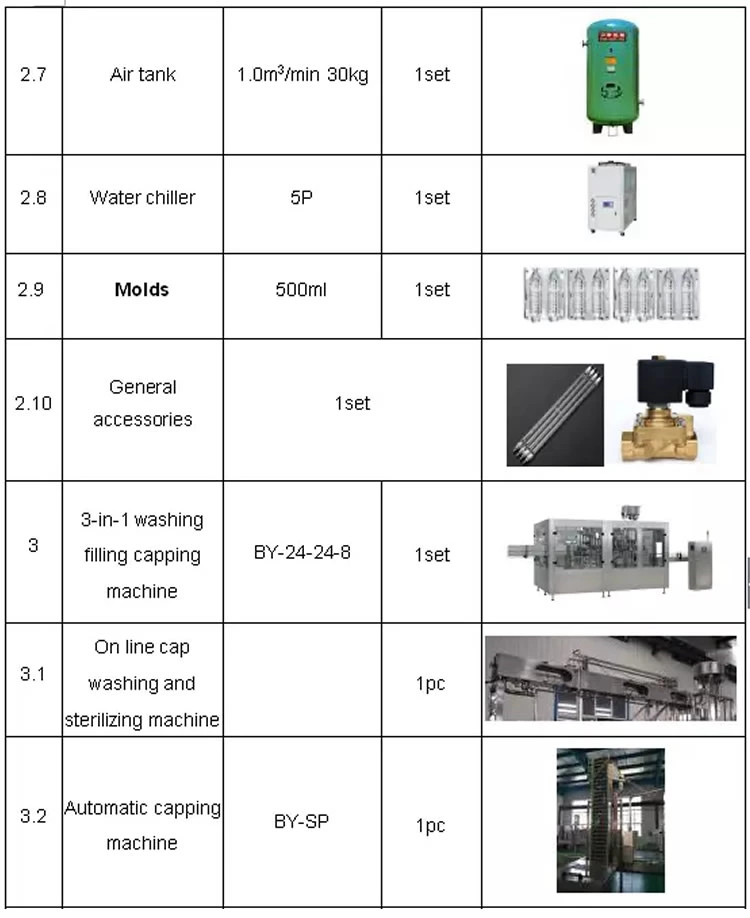

(2) Primary packaging: Does the bottle blowing machine use centralized heating, full electric production or semi-automatic production? Does the filling machine with the multi-channel cleaning function for the bottle? What process is used to sterilize the lid?

(3) Secondary packaging: The sleeve labeling machine chooses heat shrink, hot melt adhesive or self-adhesive. Does the bottle body need to be affixed with a two-dimensional code. Packaging equipment, choose paper bag, ordinary film bag or color film bag? How many bottles per one bag?

In addition to the above aspects, there are many details that require multiple services from the team and thecommunication between supply and demand.

2. Capacity selection

The production capacity is mainly determined according to market demand, sales capacity, investment budget and profit target.

(1) Evaluate the population number of the area where the factory located: 6000 BPH for population of 200,000 or more, 12,000 BPH for population of 500,000 or more, and 24,000 BPH for population of 1 million or more. The product can be radiated :small bottles of drinks are generally within 500KM, while 5 gallons of bottled water within 200KM.

(2) Investigate the sales of the counterparts: understand the production capacity and sales of factories in this city or neighboring cities;

(3) If it is a special beverage product, the production capacity is generally smaller than the bottled water project.

3. The degree of automation

It can be adjusted accordingly by the development level of the local economy, the technical strength of competitors, and the investment budget. Analyze which ones can be automated and which are lower? From the technical perspective, can it enhance the competitiveness of an enterprise?

4. How to purchase in batches

In the case of multi-stage projects, which ones should be bought first, which ones should be bought later, which ones should be guaranteed first, and which ones can be increased by increasing the number of single units later? It needs to be analyzed according to the type of products put into production and the characteristics of the process.

5. How to choose a supplier

Very few companies can complete the manufacture of a production line of equipment. Therefore, in addition to the performance of a single machine, the performance of the entire line must also be considered. Is it supplied by one company, or divided into several companies.If purchasing from different companies, how to control the final product quality of the entire line? How to connect with installation, commissioning, personnel training and after-sales service? All must be considered comprehensively based on your own strategic planning and industry experience.