12000bph Carbonated Drinks Juice Whole Production Line

- Size:

- 5500*4500*2300mm

- Capacity:

- 12000BPH

- Weight:

- 9500

- Power:

- 18kw

- Type:

- FILLING MACHINE

- Voltage:

- 220/380v

- Driven Type:

- Electric

- Automatic Grade:

- Automatic

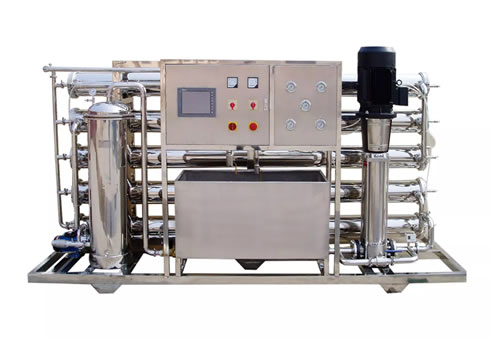

Water Treatment System

Equipment Performance

All stainless steel structure, American Dow reverse osmosis membrane; frequency converter control, can dynamically adjust working pressure to adapt to different TDS value of raw water; automatic flushing, cleaning pre-filter and reverse osmosis membrane; online water quality detection, automatic output measurement.

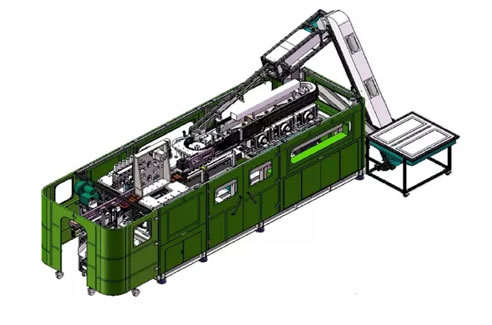

Automatical Bottle Blowing Machine

Equipment Performance

Multiple servos are precisely controlled and operate stably; high-pressure air is automatically recovered, and the action cylinder does not require a low-pressure air source; the star wheel dial enters the bottle, centralized heating, saving electricity; variable-pitch bottle blowing, can blow 0.25L -1.5L bottles type.

Quality Control

All of our products are designed with CAD.Major parts are all processed with CNC lathes and machining centers and then fitted and assembled in the dedicated room to assure the accuracy of fitting and the cleanness of parts.Most of the components and accessories are of famous brands domestic and world wide.Each machine must be subjected to 80~100hrs uninterrupted operation test before delivered.

Beverage Preparation System (6T/H)

| Pre-treatment system | 3 flavor, mixing, filtration, hot water, storage, CIP, control system | 1 set |

| High power carbon mixer | 6T/H | 1 set |

| Water chiller | 180WDSM4CT | 1 set |

| Spray and warming machine | 1.5m*12m | 1 set |

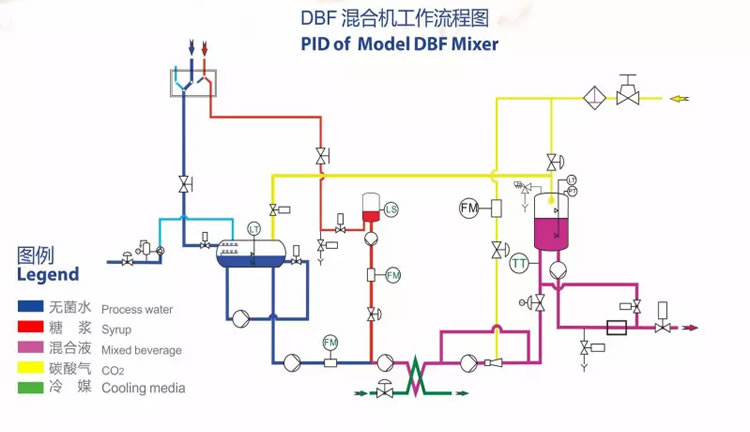

Gas-liquid Mixer

DBF series Online Flow Meter Type Mixer

The mixer is composed of a vacuum deaerator,a CO2 injector, a plate heat exchanger, a finished product tank an inline CO2 and brix detector(optional),machine frame, electric cabinet, and other parts,The fully automatic control system consists of individual systems to control pressure, liquid level,temperature and other machine operation parameters such as brix and gas volume. High efficiency dearation system. High accuracy brix control. Stable and accurate carbonation. Lowest wastage. Bxix/CO2 meter available. BY-32-32-10 Three in One washing filling

Three in One washing filling capping Machine

Boyuan Carbonated drinking Filling machine: This machine is combined with rinsing, filling and capping, which special designed for PET bottled still water. It is stable characteristic, advanced technology, nice appearance and complete function.

Main configuration:

- Material of filling valve: Stainless steel SUS316L.

- Material of rotary tray and machine platform of rinser and filler: Stainless steel SUS304.

- Main motor: ABB (Switzerland)/ SEW (Germany).

- Sliding bearing: Igus (Germany).

- Frequency inverter: DANFOSS (Denmark).

- Touch screen: SIEMENS (Germany).

- PLC: SIEMENS (Germany).

- Contactor/ Air switch/ Breaker: SCHNEIDER (France).

- Pneumatic components: CAMOZZI (Italy).

- Seals: Busak+Shamban (U.S.A)/ SEALTECH (HK).

- Photocell switch: TURCK (Germany). 12. Proximity switch: TURCK (Germany).