Our design is considered from the following aspects:

1. The quality of the product: mainly includes the quality of the content and packaging, which must meet the requirements of government management departments, and also meet the requirements of brand planning;

2. the stability of the product, the performance Open two shifts per day, each shift is more than 8 hours;

3. The output: the output that meets the technical requirements and the output required by marketing planning;

4. Energy consumption: meets the internationally higher energy-saving standards;

5. The degree of automation: guarantees rapid mold replacement and suitable operation labor costs;

6. Installation / commissioning / personnel training: Considering the local level of talents and skills, and the supply of relevant raw materials, we provide technical engineers with many years of experience to ensure the smooth commissioning of the project;

7. Equipment maintenance cost and convenience: Adhere to mature design technology and lean production process to ensure product manufacturing accuracy; at the same time provide sufficient accessories in the follow-up; to ensure stable and long-term operation of the project.

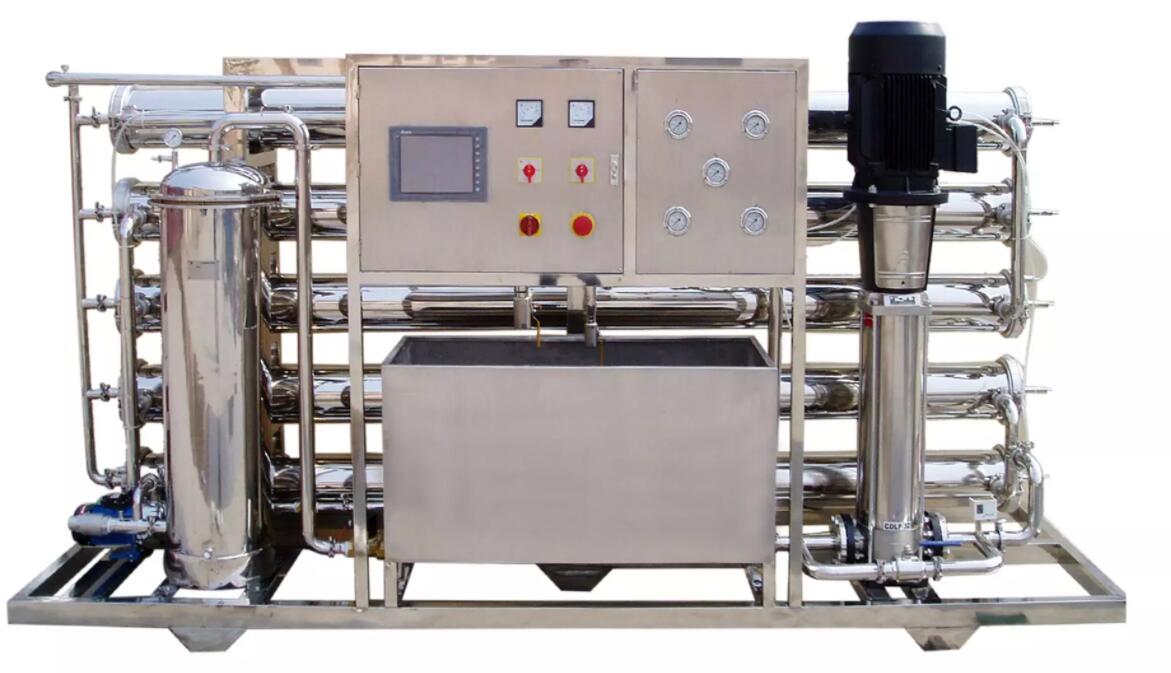

Water Treatment System

Equipment Performance

All stainless steel structure, American Dow reverse osmosis membrane; frequency converter control, can dynamically adjust working pressure to adapt to different TDS value of raw water; automatic flushing, cleaning pre-filter and reverse osmosis membrane; online water quality detection, automatic output measurement.

Automatical Bottle Blowing Machine

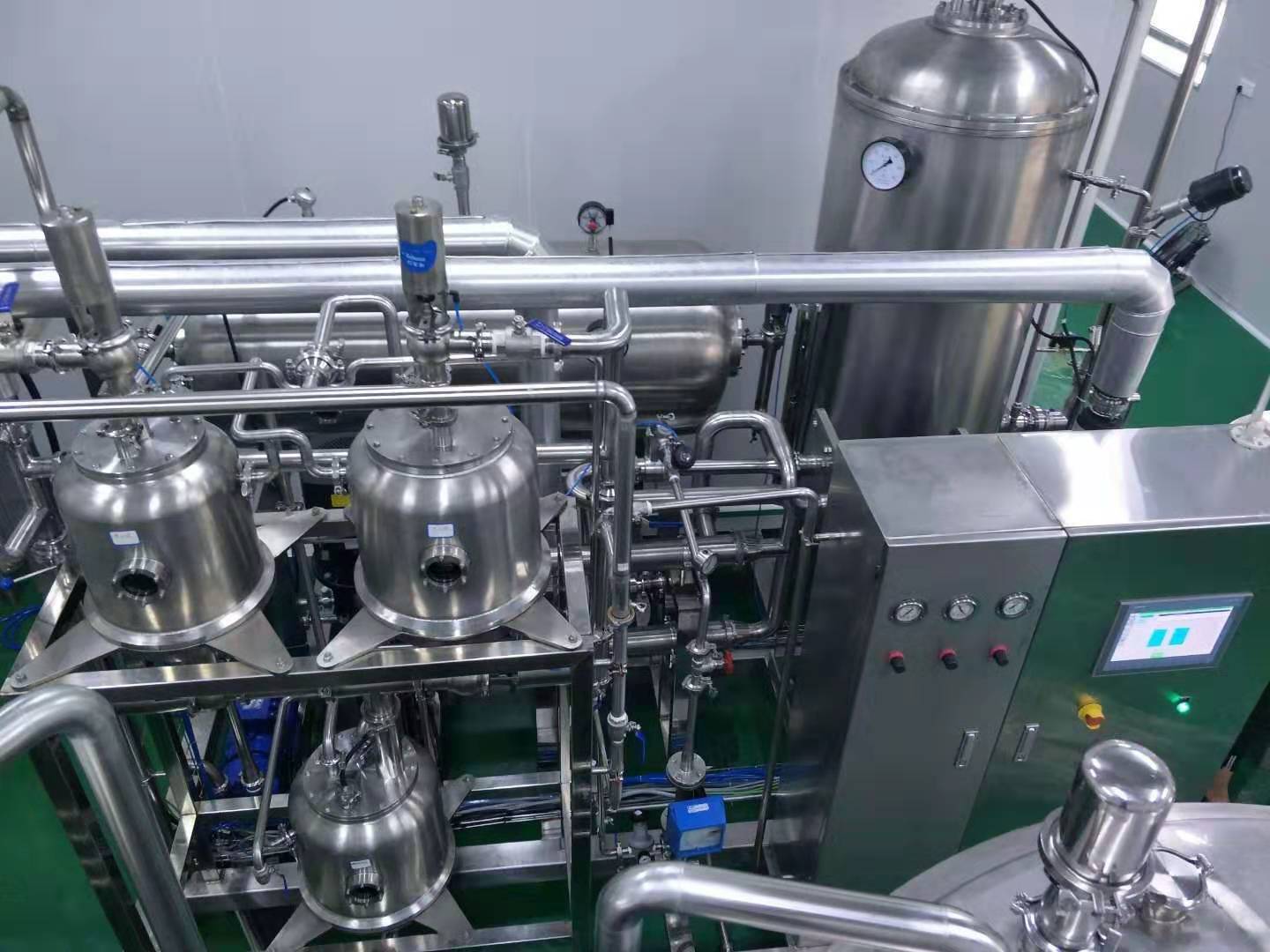

Beverage Preparation System (6T/H)

Gas-liquid Mixer

DBF series Online Flow Meter Type Mixer

The mixer is composed of a vacuum deaerator,a CO2 injector, a plate heat exchanger, a finished product tank an inline CO2 and brix detector(optional),machine frame, electric cabinet, and other parts,The fully automatic control system consists of individual systems to control pressure, liquid level,temperature and other machine operation parameters such as brix and gas volume.

High efficiency dearation system.

High accuracy brix control.

Stable and accurate carbonation.

Lowest wastage.

Bxix/CO2 meter available.

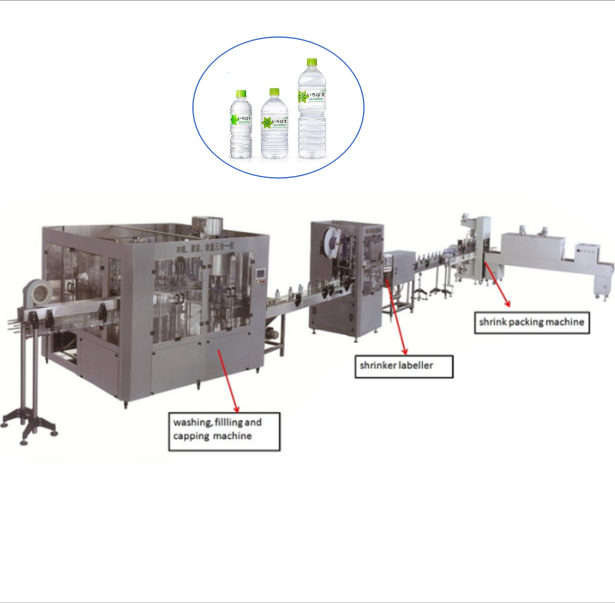

Three in One washing filling capping Machine

Carbonated drinking Filling machine: This machine is combined with rinsing, filling and capping, which special designed for PET bottled still water. It is stable characteristic, advanced technology, nice appearance and complete function.

Main configuration:

1. Material of filling valve: Stainless steel SUS316L.

2. Material of rotary tray and machine platform of rinser and filler: Stainless steel SUS304.

3. Main motor: ABB (Switzerland)/ SEW (Germany). 4. Sliding bearing: Igus (Germany).

5. Frequency inverter: DANFOSS (Denmark). 6. Touch screen: SIEMENS (Germany).

7. PLC: SIEMENS (Germany). 8. Contactor/ Air switch/ Breaker: SCHNEIDER (France).

9. Pneumatic components: CAMOZZI (Italy). 10. Seals: Busak+Shamban (U.S.A)/ SEALTECH (HK).

11. Photocell switch: TURCK (Germany). 12. Proximity switch: TURCK (Germany).

Linear Hot Melt Glue Adhesive Labeling Machine

Product Introduction

Linear OPP hot melt glue adhesive labeling machine is the newest continuous operation of the labeling machine.

The mainly used for container labeling cylindrical shape of detergents, beverages, mineral water, food etc. The material of label is using environmentally material of OPP films. It can be automatically oxidative decomposition and reduce production costs by more than 30 percent.

Labeling machine is control by PLC touch screen, all electric eye is using imported advanced configuration. This labeling machine with high speed, high accuracy, stable performance, easy to operate and look elegant appearance.

Single Roller Film Wrapping Machine

Main Character

1. Classic shape, beautiful, novel structure, unique, easy operation and maintenance.

2. The use of pneumatic expansion support film roll, electronic sensor film delivery, sending film stable, fast and convenient for membrane.

3. Three sets of servo control system: The spindle, the upper film and the cutting film are all advanced servo control, which is accurate, stable and reliable.

4. Unique “bottle vibration” can make the product smooth separation, avoiding the phenomenon of squeeze bottle.