Working Principle And Performance Of Sanitary Pump

Sanitary Pump It is necessary to pay attention to improving the reliability and life of the electric pump. Pay attention to the appearance quality of the submersible electric pump and gradually enter the international market. my country's submersible electric pumps have obvious price competitive advantages in the international market. In particular, the appearance quality of the submersible electric pump should be improved to give users a sense of beauty, so that domestic submersible electric pumps can enter the international market as soon as possible. Therefore, since the submersible electric pump itself and the pump station that uses the submersible electric pump have many advantages. In the future, my country's demand will continue to grow, and there will be the following main development trends. Generally, the cost can be reduced by 40% and the construction period can be shortened by 1/22/3. 1. Develop large and medium-sized submersible electric pumps. Large and medium-sized submersible electric pumps have the outstanding advantages of simplifying the pump structure and saving investment in pump station construction. They will be more and more widely used in municipal, industrial and mining, environmental protection, and industrial and agricultural water supply and drainage. It is expected that the demand will be large in the future. For example, pumps with cutting devices, multi-stage pumps, submersible electric pumps for pumping corrosive media, etc. are still rarely produced. 2. Develop multi-functional and multi-purpose submersible electric pumps. The forms of submersible electric pumps in my country are not enough compared with the products of famous foreign submersible electric pump manufacturers. However, the market demand is very large, so it has a good development prospect. Two single-end mechanical seals are used.

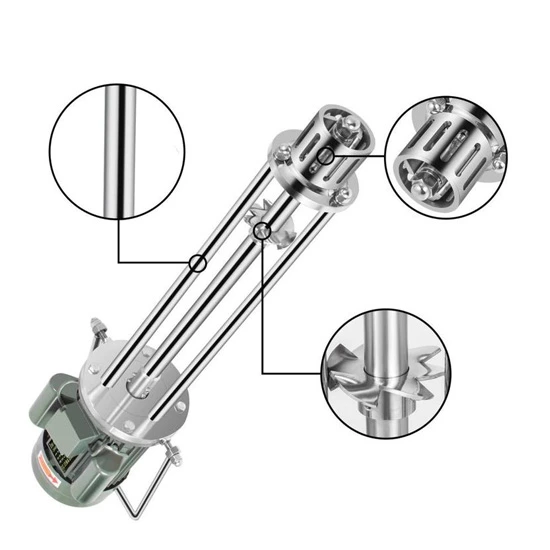

3. Develop high-reliability mechanical seals. Mechanical seals are the key parts of submersible electric pumps. In this way, the pressure of the medium can act on the end face, and the leakage direction is inward flow type. These are all favorable, but the structure is slightly complicated. The oil chamber is equipped with a double-end mechanical seal, and the end faces on both sides should adopt different structural types so that the pressure of the medium can act on the end face on the lower side. Otherwise, only relying on the spring force, the reverse thrust of the sealing end face is easy to open the end face. Therefore, further research should be conducted on the structure and materials to improve its reliability and life. All these materials should be applied to submersible electric pumps as soon as possible.

4. New materials, new technologies, new processes, etc. will be gradually applied. Ordinary pumps have used stainless steel, fluoroplastics (F46 lining plastic), lining rubber, spray ceramics, etc. Expand the application field of submersible pumps. The application of new technologies and new processes such as computer-aided design, auxiliary manufacturing and auxiliary testing is also imperative. Facts have proved that the application of new technologies, new materials, and new processes not only liberates labor productivity, but also ensures stable and reliable product quality.