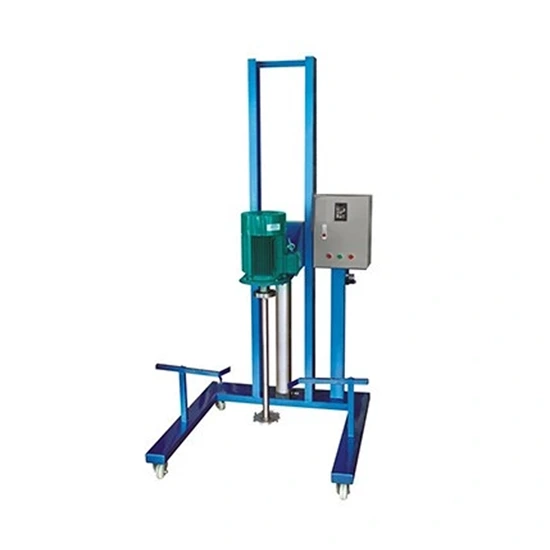

Two-axis High-speed Disperser (adjustable Operating Frequency)

Model selection of High Speed Disperser:

1. The fast disc feeder is selected according to its own performance and characteristics according to the material characteristics.

Double-axis dispersion, test disperser, two-axis dispersion, two-axis four-disc.

2. Select according to the different properties of the water-based materials and oils produced by itself.

Frequency conversion stepless speed regulation, electromagnetic induction stepless speed regulation control, explosion-proof inverter stepless speed regulation

3. Select up and down according to the specific use steps of the production plan

Electric hydraulic lifting, fixed (no adjustment function)

4. Select the appropriate model of high-speed disperser according to the power size.

Output power: 2.2kw-95kw optional

Two-axis high-speed disperser (adjustable working frequency) is an introduction to industrial disperser manufactured by overseas technology, with smooth elevator, reliable operation, low noise, hydraulic lift, standing or standing installation, not only with cutting disperser, fast disperser function, but also uses a more unique two-axis customized overall structure is relatively new, unique, also help to improve the disperser efficiency, in the current market by the majority of customers. The components are made of high-quality materials, paint, coatings, medicines, food, cosmetics and other viscous liquid melting, mixing, dispersion equipment.

Features of two-axis high-speed disperser

1. There are two sets of dispersion system software, the dispersion level is much greater than the double-axis disperser.

2. The upper and lower ends of the dispersion shaft are safe, and the two ends of the bearing assembly span effectively prevent the dispersion shaft from shaking.

3. The size and serration height of the dispersion disc can be selected according to the characteristics of the scattering medium, and the production range is very wide.

4. Hydraulic lifting and dispersing machine can rotate 360° at the same time. The function of elevator and breathing is closely integrated. The high-speed dispersing machine can quickly switch to another cylinder for dispersing. The high-performance two-axis fast disperser is generally equipped with 2 to 4 dispersing cylinders, and the manufacturing cost is lower.

5. The dispersing shaft is treated with stainless steel hard chrome after quenching heat treatment, and has the characteristics of high coaxiality, high parallelism and strong smoothness.

6. Synchronous belt transmission system, no noise during operation, and can also play a buffer and vibration function. For example, sometimes the belt will automatically deviate when overloaded to protect other parts.

7. Use hydraulic lifting to adjust the relative height of hydraulic lifting according to the material angle of the dispersing barrel, so that the dispersing plate is installed on the barrel to facilitate the dispersing working position.

Generally speaking, fine production materials and other materials need to be ground and dispersed. When choosing some products, as long as they are all dispersed or fine, can you choose grinding equipment to grind? Or disperser? To put it simply, the ceramic sand mill is also called a grinding device, which is usually used to grind and disperse the raw materials. The material is dispersed in the drum motor rotor to grind the material, and its particle size is relatively high. The disperser is also called a stirrer, which uses a rotary table to rotate the equipment for mixing and shaping.