This Variable Frequency High-speed Emulsifier Makes Your Production Efficiency Higher

The variable frequency high-speed emulsifier has good emulsification effect and conveying capacity, the bearing seat has a reasonable structure and good running stability; the outlet of the working head, the second-stage stator seat, and the first-stage stator seat are respectively equipped with cooling water or heating liquid jackets, which also ensure that the variable frequency high-speed emulsifier can be applied to a wider range of product applications.

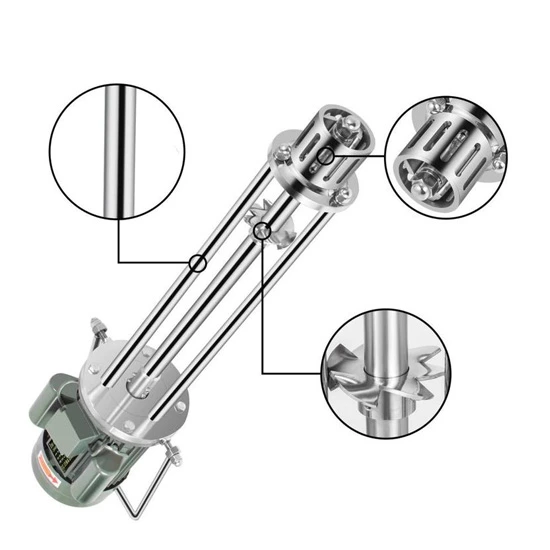

High Shear Emulsifier is a high-performance equipment used for continuous production or cyclic processing of fine materials. In the cavity of a narrow space, 1-3 sets of dual-bite multi-layer stators and rotors are installed. The high-speed rotating rotor quickly sucks the material into the rotor cavity. Due to the high circumferential speed generated by the high-speed rotation of the rotor and the strong kinetic energy brought by the high-frequency mechanical effect, the material is subjected to strong mechanical and hydraulic shearing, centrifugal extrusion, liquid layer friction, impact tearing and turbulence in the narrow gap between the stator and the rotor. The combined effects of the immiscible solid phase, liquid phase, and gas phase are instantly and evenly dispersed and emulsified under the joint action of the corresponding mature process and appropriate additives. After high-frequency reciprocating, it is subjected to strong shearing and dispersion, and finally a stable high-quality product is obtained.