The Influence Of Emulsification Head On The Emulsification Effect Of Materials

High Shear Emulsifier is a mechanical equipment that can evenly mix water-phase materials and oil-phase materials. Cosmetic companies need to use vacuum homogenizing emulsifiers to produce emulsions. In the production process of cream cosmetics, the stability of cream cosmetics emulsions determines the quality of cosmetics. So for emulsification equipment, what factors affect the emulsification effect of materials?

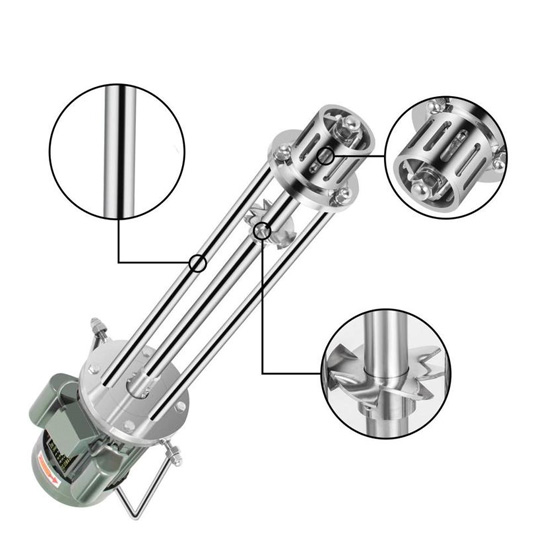

Form of emulsification head: There are two types of emulsification heads: batch type and continuous type, among which the continuous emulsification head is better than the batch type.

Shear rate of emulsification head: Normally, the greater the shear rate of the emulsification head, the better the emulsification effect.

Tooth structure of emulsification head: The emulsification head is divided into primary teeth, medium teeth, fine teeth, and super fine teeth. The finer the teeth, the better the effect.

The residence time of the material in the dispersion wall, the emulsification dispersion time: the less the residence and dispersion time, the better the effect.

Number of cycles: During the emulsification process, multiple homogenization dispersion emulsifications are required, and multiple cycles are required to achieve the emulsification effect target.

The above factors are not applicable to all materials. Customers also need to analyze specific problems based on various factors such as material viscosity, required process, output, etc.