Structural Characteristics And Functions Of Intermittent High Shear Emulsification Head

The vacuum homogenizer is a mechanical device that uses High Shear Emulsifier to quickly and evenly distribute one phase or multiple phases in at least another continuous phase under vacuum, and uses the action of the stator and rotor to evenly mix the water phase material and the oil phase material. Today, let's learn about the structure and function of the intermittent high shear emulsifier.

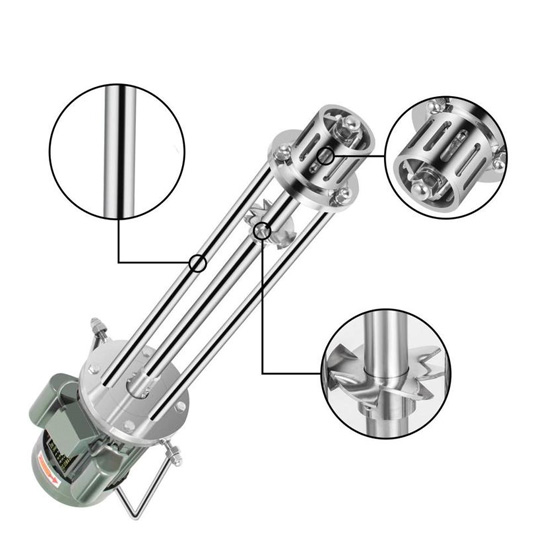

◆ The intermittent high shear emulsifier is a type of emulsifier. The emulsifier is an emulsifier installed at the top or bottom of the tank equipment. The different stator and rotor structures of the emulsifier can produce different emulsification effects on the material.

◆ The intermittent high shear emulsifier is achieved through the precise matching of the rotor and the stator. The rotor rotates at high speed and smoothly, forming high-frequency, strong circumferential tangential speed, angular speed and other comprehensive kinetic energy performance.

◆ Under the action of the stator, strong, reciprocating hydraulic shear, friction, centrifugal extrusion, liquid flow collision and other comprehensive effects are formed in the reasonably narrow gap between the stator and the rotor. The rotor and stator of the intermittent high shear emulsification head adopt a claw structure, two-way suction, high shear efficiency, and after high-frequency reciprocating cycles, a bubble-free and delicate product is finally obtained.