Starting Today, Manufacturers Have Begun To Use Variable Frequency Emulsifiers

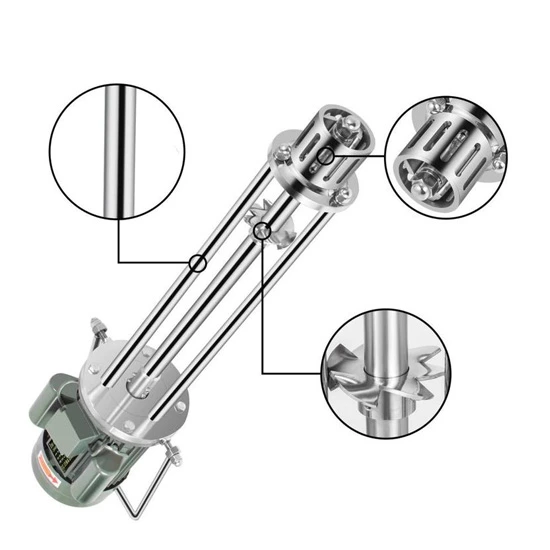

The output shaft of the motor of the variable frequency emulsifier is connected to the main shaft through a coupling, the bearing seat and the motor are fixed on the base, the bearing seat is connected to the machine seal seat flange, the machine seal seat is connected to the working head flange, a mechanical seal is provided between the machine seal seat and the main shaft, a cooling water jacket is provided on the machine seal seat, and the working head is provided with an outlet, a second-stage stator seat, a first-stage stator seat, a first-stage stator, a first-stage rotor, a pressure plate, a sleeve, a second-stage stator, a third-stage stator, a hexagonal head pipe plug and a third-stage rotor from the inside to the outside; the outlet of the working head, the second-stage stator seat and the first-stage stator seat are respectively provided with cooling water or heating liquid jackets.

The homogenization system of High Shear Emulsifier is divided into upper homogenization and lower homogenization, internal and external circulation homogenization, and the stirring system is divided into one-way stirring and two-way stirring, and ribbon stirring; the lifting system is divided into single-cylinder and double-cylinder lifting, and various high-quality products that meet the needs can be customized according to customer requirements; the variable frequency emulsifier adopts imported frequency converter speed regulation to meet the production needs of different processes; the homogenization structure of the variable frequency emulsifier adopts imported double-end mechanical sealing effect, the maximum emulsification speed can reach 4200 rpm, and the maximum shear fineness can reach 0.2-5um;

The variable frequency emulsifier adopts vacuum suction, especially for powder materials to avoid dust flying; the main pot cover can be equipped with a lifting device, which is convenient to clean and has a more significant cleaning effect, and the pot body can be selected for dumping; the pot body is welded with three layers of imported stainless steel plates, and the tank body and pipeline are mirror polished, which fully meets the requirements.