Let’s Take A Look At The Equipment Needed To Produce These Pet Liquid Ointments!

The production of pet liquid ointment is a complex process involving multiple steps and equipment. In order to ensure the quality and safety of the product, the following are some essential equipment in the production process of pet liquid ointment:

1. Mixing equipment

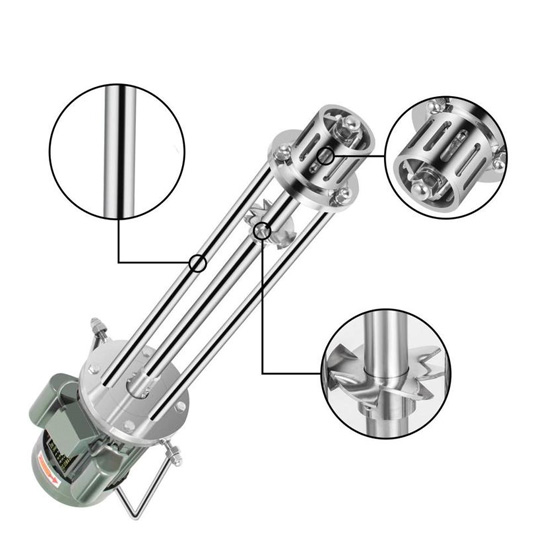

Mixing equipment is one of the core equipment in the production of pet liquid ointment. Its main function is to mix different raw materials to ensure that the components are evenly distributed.

Commonly used mixing equipment includes stirring tanks, mixing tanks and High Shear Emulsifier, etc.

These equipment can effectively mix the raw materials evenly, laying a good foundation for subsequent processing.

2. Heating and cooling equipment

In the production process of pet liquid ointment, heating and cooling equipment are indispensable. Heating equipment is mainly used to heat the raw materials to the appropriate temperature to promote their dissolution and mixing.

And cooling equipment is used to cool the mixed liquid ointment to room temperature for subsequent packaging and storage.

Commonly used heating equipment includes steam heaters and electric heaters, while cooling equipment includes water-cooled coolers and air-cooled coolers, etc.

3. Vacuum equipment

In the production process of pet liquid ointment, vacuum equipment is mainly used to remove bubbles and air from the mixed liquid to ensure the stability and quality of the product.

Vacuum equipment can effectively reduce the risk of oxidation and deterioration of products during storage and transportation. Commonly used vacuum equipment includes vacuum pumps and vacuum tanks.

4. Packaging equipment

Packaging equipment is the last process in the production of pet liquid ointment. Its main function is to package the produced liquid ointment for storage and sales. Commonly used packaging equipment includes filling machines, sealing machines and labeling machines.

These equipment can quickly complete the packaging process, improve production efficiency, and ensure the hygiene and safety of the product.

5. Auxiliary equipment

In addition to the core equipment mentioned above, some auxiliary equipment is also required in the production process of pet liquid ointment to support production.

For example, conveyor belts are used to transfer raw materials and finished products between different equipment; filters are used to remove impurities and particulate matter in raw materials; meters are used to accurately measure the amount of raw materials added, etc.

Although these auxiliary equipment are not directly involved in the production process like core equipment, they are also important for ensuring product quality and production efficiency.

In short, pet liquid ointment production requires a series of equipment to support the entire production process.

These equipment can not only ensure the quality and safety of the product, but also improve production efficiency and reduce production costs.

Therefore, when selecting and using these equipment, pet liquid ointment manufacturers need to fully consider their actual needs and production scale to ensure that they choose the most suitable equipment.

At the same time, they also need to regularly maintain and maintain the equipment to ensure the normal operation and service life of the equipment.

Only in this way can high-quality, safe and reliable pet liquid ointment products be produced to meet the needs of consumers.