Industrial Production Of Tibetan Medicine Requires This Vacuum Emulsifier

Industrial production of Tibetan medicine requires such a High Shear Emulsifier!

First of all, we need to deeply understand the production process of Tibetan medicine, the characteristics of raw materials, and the application and advantages of vacuum emulsifiers in the pharmaceutical industry.

Tibetan medicine, as a treasure of traditional Chinese medicine, has been protecting the health of people in the plateau area for thousands of years with its unique theoretical system, rich drug resources and remarkable curative effect.

As a key equipment in modern pharmaceutical and cosmetic production, the vacuum emulsifier is essential to improve product quality with its efficient and precise mixing and emulsification capabilities.

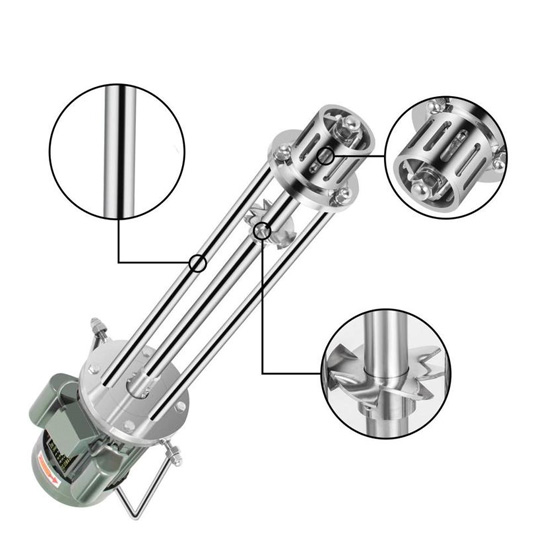

Tibetan medicine vacuum emulsifier

### The particularity of Tibetan medicine production

Tibetan medicine production often follows ancient methods, emphasizing nature, purity and harmony.

The raw materials are mostly taken from natural resources such as animals, plants, minerals, etc. that are unique to the Qinghai-Tibet Plateau. These raw materials have strict regulations on collection, processing and compatibility.

Tibetan medicine preparations are diverse in form, including powders, pills, pastes, decoctions, etc. The preparation process of each preparation has its own unique process and requirements.

For example, some Tibetan medicines require long fermentation, soaking or grinding to fully release the active ingredients in the medicinal materials;

Others may be obtained through specific decoction or distillation methods to obtain the required medicinal liquid or essential oil.

### Function and application of vacuum emulsifier

As the name suggests, the vacuum emulsifier is a device that emulsifies and mixes materials under a vacuum environment.

Its working principle is to disperse two or more immiscible liquids into emulsions evenly and stably through high-speed shearing, impact and mixing.

In this process, the vacuum environment can effectively prevent the material from oxidizing and deteriorating at high temperatures, while removing bubbles in the material and improving the fineness and stability of the product.

In the pharmaceutical industry, vacuum emulsifiers are widely used in the production of dosage forms such as creams, lotions, gels, etc., especially in preparations that require high dispersion, homogenization and protection of active ingredients. Its advantages are particularly obvious.

### Industrial production of Tibetan medicine requires such a vacuum emulsifier

With the development of science and technology, more and more Tibetan medicines are beginning to try to adopt modern dosage forms, such as creams, gels, etc.

During the preparation of these dosage forms, it is often necessary to fully mix and emulsify the medicinal extracts and matrix materials to ensure the uniform distribution and stability of the drugs.

At this time, the vacuum emulsifier becomes an indispensable equipment. It can not only improve production efficiency, but also effectively protect the active ingredients in the medicinal materials and ensure the quality and efficacy of the preparations.