How To Properly Clean The Homogenizing Head Of A High Shear Emulsifier

As the name suggests, the emulsifying machine is a machine that can shear materials at high speed. It can fully refine and mix the materials evenly, which means it can cut, mix and emulsify the materials at high speed. Among them, the homogenizer head, or homogenizer or emulsifier, is its core part. Therefore, when using and maintaining it, you must pay attention to the cleaning and maintenance of the homogenizer. Below, the editor of Yuxiang will take you to see some of them. Cleaning and maintenance suggestions!

High Shear Emulsifier pay more attention to keeping the homogenizer clean:

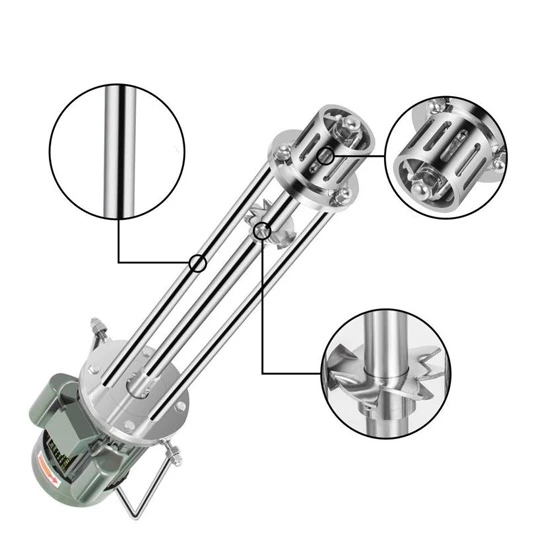

When the machine is no longer in use or another material is to be replaced, in order to ensure the cleanliness and hygiene of the next batch of materials, the homogenizer part needs to be cleaned as required. The parts of the homogenizer that are in contact with the working fluid should be cleaned as required, especially the cutting wheel on the head, the cutting sleeve, the sliding bearing and the sleeve in the homogenizing sleeve. These should be removed, cleaned and reinstalled. After cleaning and reassembly, turn the impeller by hand. There should be no sticking phenomenon. After the two flanges of the pot body and pot lid are relatively fixed, the homogenizer motor can be rotated correctly and there are no other abnormalities, and the operation can be started. In addition, it should be noted that due to the high speed of the homogenizing head, it cannot be operated when the emulsification pot is empty, so as to avoid local heating and affecting the sealing degree.