Emulsified Type - "oil-water Balance" In Emulsified Cutting Fluid

"Oil-water balance" in emulsified cutting fluids

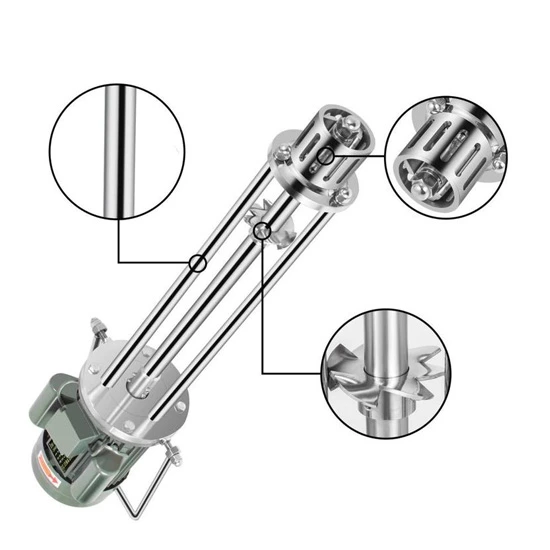

The cutting fluids prepared with High Shear Emulsifier can be divided into three categories according to their formula structure characteristics: pure oil type, emulsified type, and fully synthetic type, which are respectively called cutting oil, emulsified cutting fluid, and fully synthetic cutting fluid.

In the process, emulsified cutting fluids can be regarded as emulsified pure oil products. According to the size of the emulsified oil droplets sheared by the emulsifier, they can be divided into emulsified oil (>0.1um) and microemulsified oil (<0.1μm). Compared with cutting oils and fully synthetic cutting fluids with simpler systems, the composition of emulsified cutting fluid products is more complex, and the working fluid is an O/W system, so the angles for examining its formula structure are also richer.

So far, there are three known mixed systems containing oil, water and surfactant: emulsion, microemulsion, solubilized micelle and reverse micelle solution (swollen micelle solution). Most products belong to the first two types, and a few low-oil products belong to the third type. The water content in emulsified oil is generally less than 10%, and the oil content can reach up to 80%. Its concentrate is W/O type, requiring the system to have a low HLB value to be stable. The appearance of emulsified oil dilution is often milky white and not bright. The diameter of the dispersed phase oil droplets is roughly in the range of 0.1~10um, and the wavelength of visible light is 0.4~0.8um, so the reflection of light in the emulsion is more significant. In addition, the lower limit of the size of general emulsified oil droplets (about 0.1um) is very close to the resolution limit of ordinary microscopes (about 0.2um). The water content of microemulsified oil can be as high as 30~60%, and the oil content is generally ≤30%, Its concentrate is O/W type, and the diluent is mostly transparent liquid, and the oil droplet diameter is usually 0.05~0.1um; some microemulsions with oil content as high as 50% or more can also have a water content as low as 20% or less, the concentrate is W/O type, and the diluent is a blue-white translucent liquid. It is a transitional emulsion (fine emulsion) with oil droplet size between general emulsion and microemulsion, and the droplet size is 0.1~0.4um.

1.520

Winsor found in his study of the phase composition of microemulsion systems that there may be three phase compositions of systems that can form microemulsions:

(1) Winsor type

“lower phase microemulsion”: In the O/W microemulsion system, a two-phase system consisting of microemulsion and excess oil may appear. The oil density is small and located in the upper part of the container, and the microemulsion phase is located in the lower part of the container.

(2) Winsor Type II

"Upper phase microemulsion": In the W/O microemulsion system, a two-phase system consisting of microemulsion and excess water may appear. The microemulsion phase is in the upper part of the container.

(3) Winsor II type

"Middle phase microemulsion": The phenomenon of three phases coexisting in the microemulsion system (excess water and excess oil, which is oil on the upper layer, microemulsion in the middle layer, and water on the lower layer. There is a clear interface between the layers.

The above three types are essentially the ratio of oil to water.

For the same "oil-water surfactant" system, by adjusting some physical and chemical parameters, the system phase composition can be transformed between the above three types. The simplest method is to change the relative content of the three. For example, the microemulsified oil can be preset to "oil: water <1", and then adjusting the surfactant can achieve twice the result with half the effort. Of course, the formula of the oil-water ratio requires different surfactant systems to be matched. Optimizing the combination and sufficient amount is the reliable secret.