Oral Liquid and Soap Making Machine with Magnetic Stirrer for Pharmaceutical and Daily Chemical Use

- Application:

- Viscous Fluid, Liquid

- After-sales Service:

- Online Support

- Warranty:

- 1 Year

- Mixer Type:

- Agitator

- Working:

- Convection Mixer

- Stirring Type:

- Magnetic Stirring

Basic Info.

| Application Area | Chemical | Certification | ISO |

| Mixing Drum Shape | Magnetic Stirring | Layout Type | Verticle |

| Operating type | Cycle Operating | Additional Capabilities | Customer Customization |

| Power | 1.5kw | Condition | New |

| Sealing Form | Mechanical Seal | Speed | 260rpm |

| Material | Stainless Steel | Stirring Paddle Type | Magnetic Stirrer |

| Cylinder Diameter | 1100mm | Cylinder Thickness | 5mm |

| Applicable Materials | Liquid Slurry | Processing Customization | Yes |

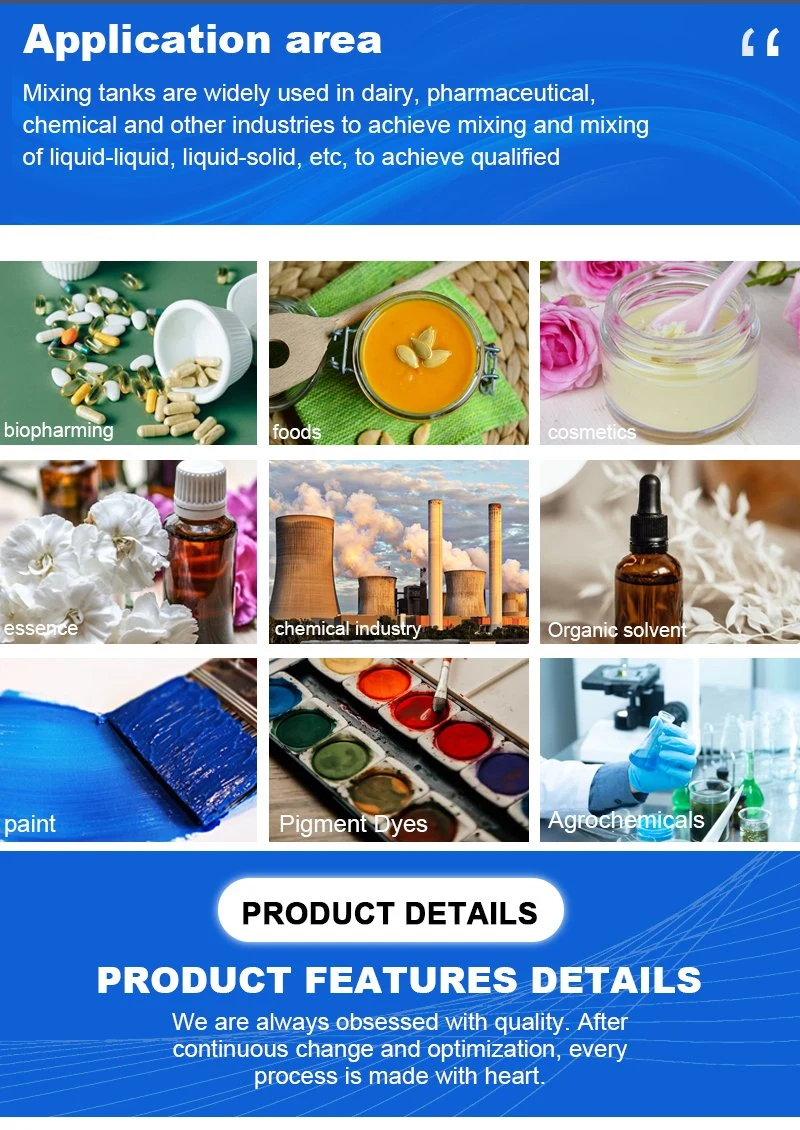

| Source of Goods | Factory Direct Deal | Applicable Fields | Biopharmaceuticals/Food and Beverage/Fine Chemical |

| Transport Package | Wooden Case | Texture of Material | 304 Stainless Steel |

| Origin | China | Specification | 1000L |

Product Overview

Mixing tank is mainly used for mixing, mixing, blending and homogenizing materials. Stainless steel mixing tank effectively shortens the mixing time, saves labor and speeds up production. It is the main equipment for modern industrial production.

Product structure

Mixing tank is composed of mixing tank body, mixing tank cover, mixer, support, transmission device, shaft seal device, etc. it can also beequipped withheating device or cooling device according to the process requirements.

Technical parameter

| Volume(L) | Cylinder Size(mm) | Motor Power(KW) | Speed(rpm) | Material |

| 50 | 300 | 0.75 | 30-180 | SUS304 / SUS316L |

| 100 | 500 | 0.75 | 30-180 | SUS304 / SUS316L |

| 200 | 600 | 1.1 | 30-180 | SUS304 / SUS316L |

| 300 | 700 | 1.5 | 30-180 | SUS304 / SUS316L |

| 500 | 900 | 2.2 | 30-180 | SUS304 / SUS316L |

| 800 | 1000 | 3 | 30-180 | SUS304 / SUS316L |

| 1000 | 1100 | 4 | 30-180 | SUS304 / SUS316L |

| 2000 | 1300 | 5.5 | 30-180 | SUS304 / SUS316L |

| 3000 | 1500 | 7.5 | 30-180 | SUS304 / SUS316L |

| 4000 | 1700 | 7.5 | 30-180 | SUS304 / SUS316L |

| 5000 | 1900 | 11 | 30-180 | SUS304 / SUS316L |

| 10000 | 2000 | 15 | 30-180 | SUS304 / SUS316L |

Note: The technical parameters of the mixing tank in the table are standard parameters, which are only for reference. We can design customized solutions according to customer needs.

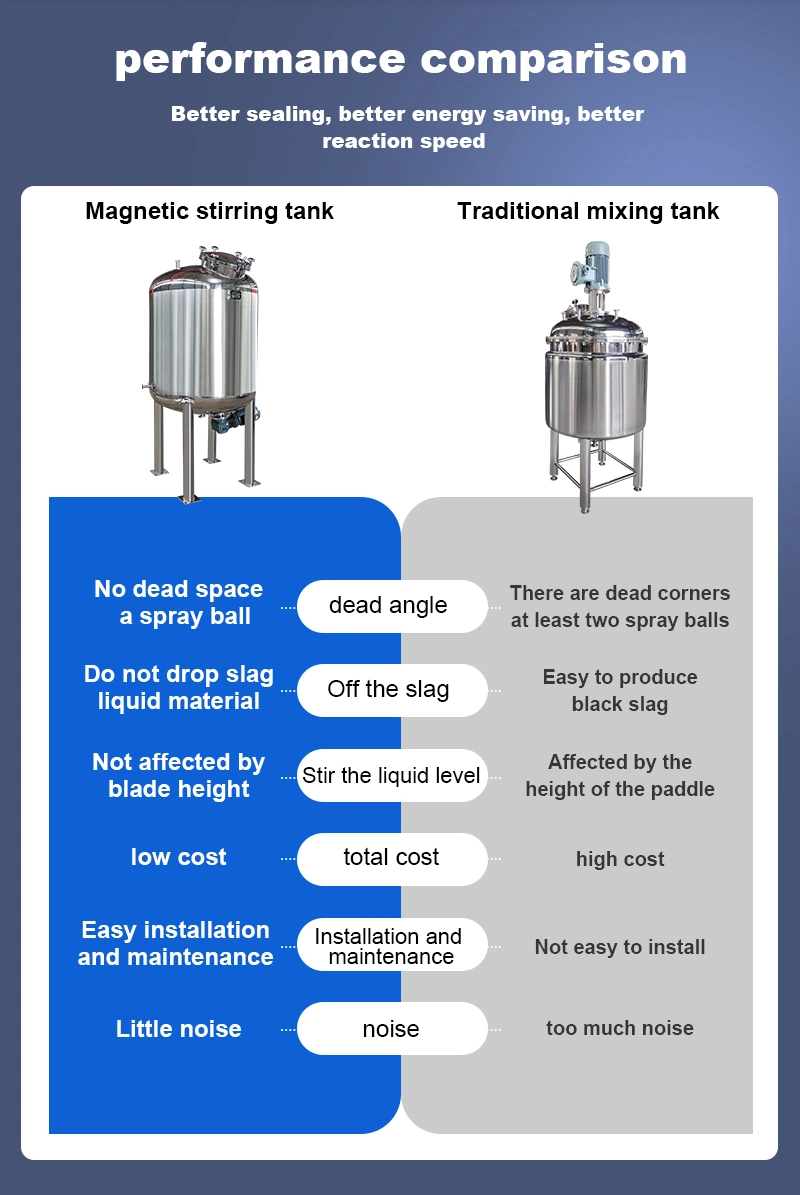

The customer of this equipment is in the pharmaceutical industry, which has high requirements for aseptic design, cleaning and sterilization, so magnetic stirring is used. It has seven advantages.

1. It completely avoids the existence of internal bubbles.

2.CIP online cleaning process is safer and more effective.

3.SIP online steam sterilization process is more simple.

4. All liquid contact surfaces can be completely discharged.

5. Low liquid level mixing installed at the bottom, easy to maintain.

6. Magnetic drive without mechanical seal, reduce the risk of contamination.

7. Excellent stirring performance.