Movable High Speed Shear SS304 or SS316 Cosmetic Mixing Tank with Agitator

- Application:

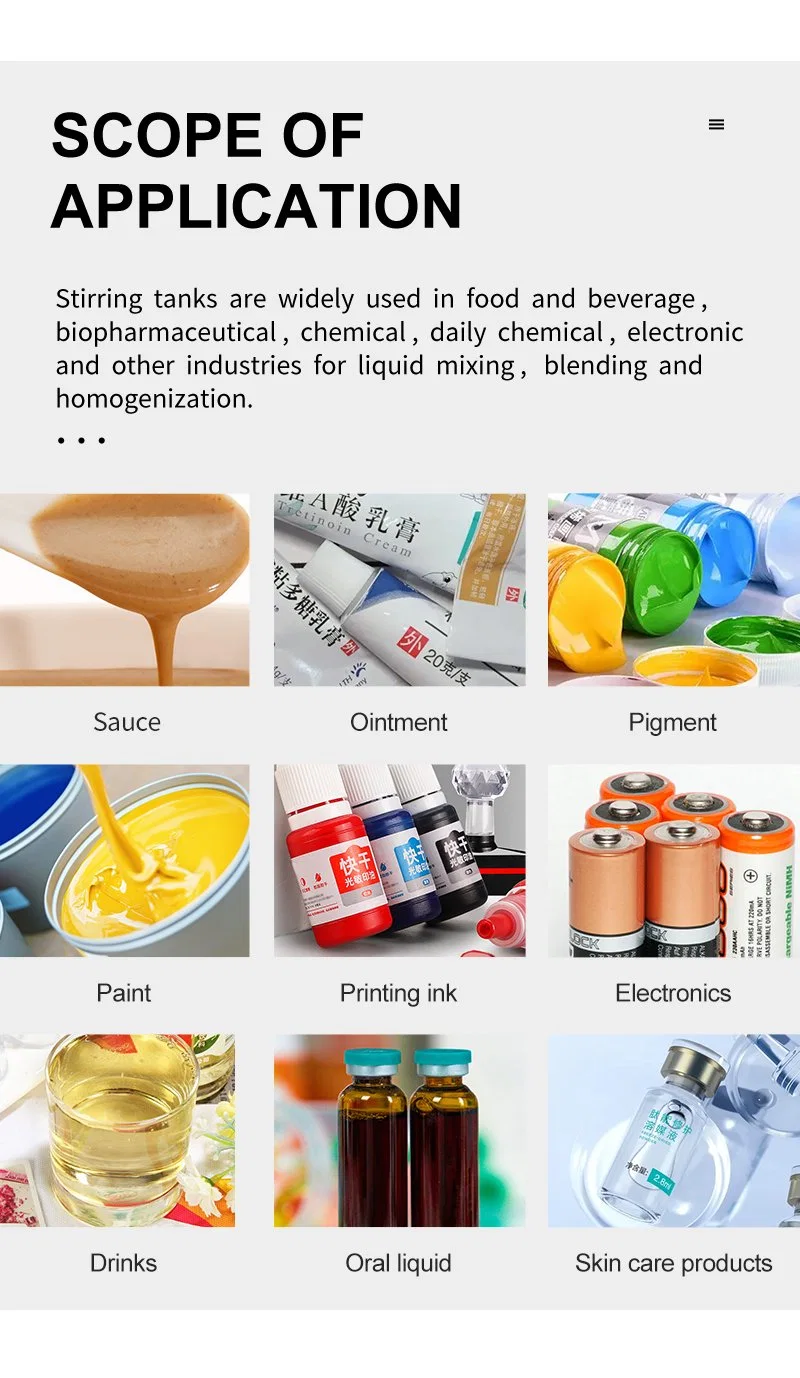

- ,Liquid, Essence,Liquid, Essence,,Liquid, Essence,Liquid, Essence

- After-sales Service:

- Online Support

- Warranty:

- 1 Year

- Mixer Type:

- Agitator

- Working:

- High Speed Mixer

- Stirring Type:

- Gear Type High-Speed Turntable

Basic Info.

| Application Area | Essence | Certification | ISO |

| Mixing Drum Shape | Customer Customization | Layout Type | Verticle |

| Operating type | Cycle Operating | Additional Capabilities | Customer Customization |

| Motor Power | 3kw | Condition | New |

| Sealing Form | Mechanical Seal | Motor Speed | 2500r/Min |

| Stirring Paddle Type | High Speed Dispersion Disc | Thermal Insulation Material | Aluminum Silicate |

| Mixing Paddle Type | Dispersed Disk | Cylinder Diameter | 650mm |

| Texture of Material | 316L Stainless Steel | Operation Method | Continuous Operation Mode |

| Control Mode | Fully Automatic | Heating Mode | Electric Heating |

| Cylinder Thickness | 4mm | Structure Type | Vertical |

| Specification | 200L | Transport Package | Wooden Box |

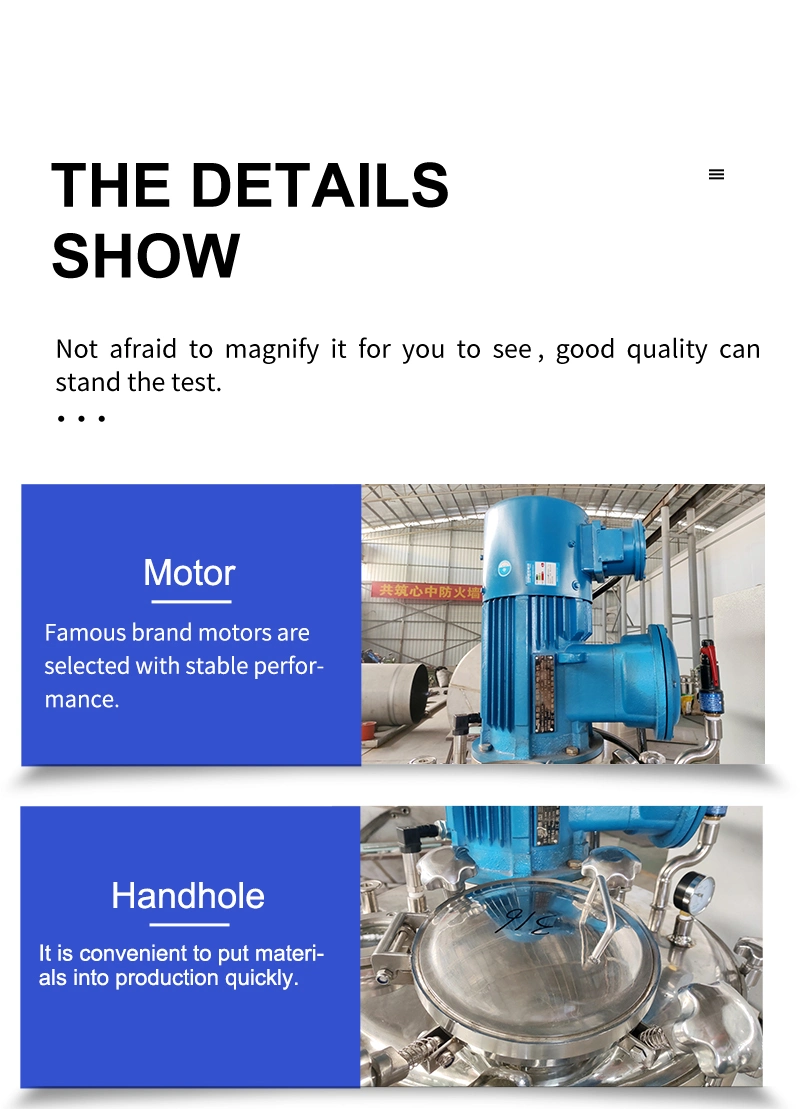

Product Overview

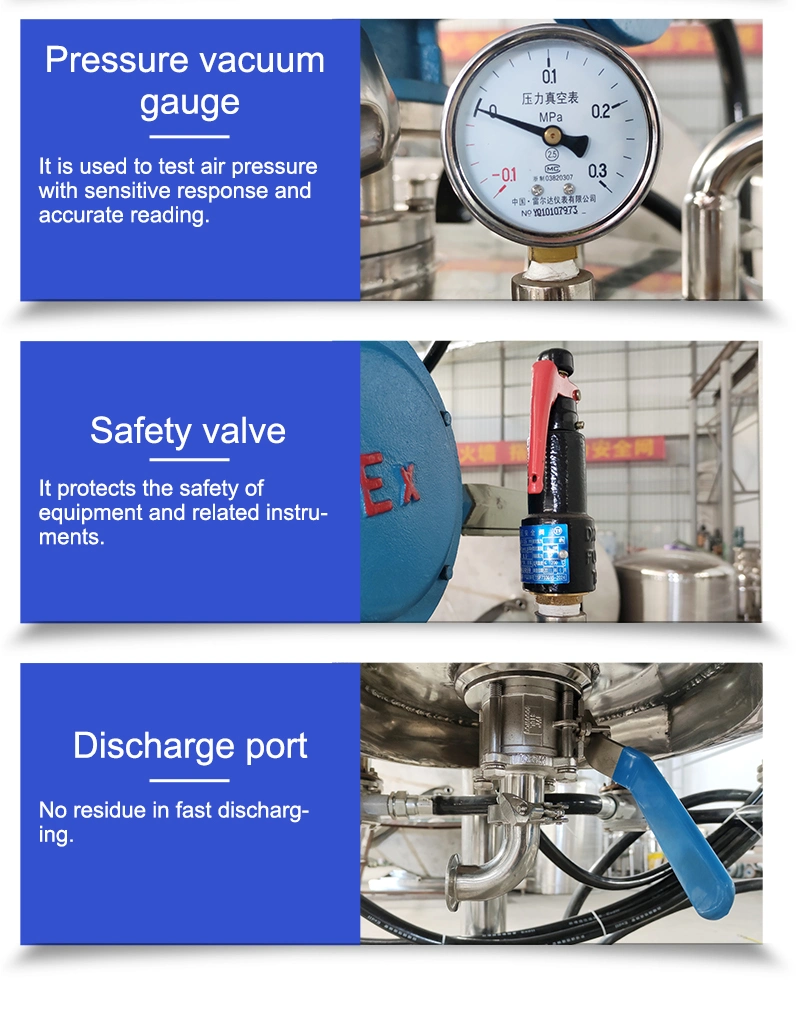

This is a dispersion mixing tank, which uses a high speed dispersion disc as the agitator to quickly crush, disperse and mix materials with different viscosities in a short time. It is one of the more advanced dispersion equipment in industrial production. The small dispersion mixing tank is mainly used for dispersion, which plays a role of partial mixing under certain circumstances, and prepares for the next process. At the same time, it can also pre disperse the materials, and the pre dispersion effect is good, which is conducive to improving the work efficiency and ensuring the quality of the processed materials.

Product structure

Mixing tank is composed of mixing tank body, mixing tank cover, mixer, support, transmission device, shaft seal device, etc. it can also beequipped withheating device or cooling device according to the process requirements.

Technical parameter

| Volume(L) | Cylinder Size(mm) | Motor Power(KW) | Speed(rpm) | Material |

| 50 | 300 | 0.75 | 0-2800 | SUS304 / SUS316L |

| 100 | 500 | 0.75 | 0-2800 | SUS304 / SUS316L |

| 200 | 600 | 1.1 | 0-2800 | SUS304 / SUS316L |

| 300 | 700 | 1.5 | 0-2800 | SUS304 / SUS316L |

| 500 | 900 | 2.2 | 0-2800 | SUS304 / SUS316L |

| 800 | 1000 | 3 | 0-2800 | SUS304 / SUS316L |

| 1000 | 1100 | 4 | 0-1400 | SUS304 / SUS316L |

| 2000 | 1300 | 5.5 | 0-1400 | SUS304 / SUS316L |

| 3000 | 1500 | 7.5 | 0-1400 | SUS304 / SUS316L |

| 4000 | 1700 | 7.5 | 0-1400 | SUS304 / SUS316L |

| 5000 | 1900 | 11 | 0-1400 | SUS304 / SUS316L |

| 10000 | 2000 | 15 | 0-1400 | SUS304 / SUS316L |

Note: The technical parameters of the mixing tank in the table are standard parameters, which are only for reference. We can design customized solutions according to customer needs.

According to the material characteristics and the user's process requirements, our company will recommend the proper type of agitator and mixing speed. The agitators suitable for low viscosity and medium viscosity fluids include propelling agitators, turbine agitators, inclined blade agitators, Brumakin agitators, plate and frame agitators, three blade backward curved agitators, MIG agitators, etc. The agitators suitable for high viscosity and ultra-high viscosity fluids include anchor type agitator, frame type agitator, spiral belt type agitator and screw type agitator. The combined agitator can also be made according to the technological requirements of users.