Jam Metal Jacketed Steam Kettle for Restaurant

- Type:

- Cooking Equipment, Cooking Equipment

- Warranty:

- 1 Year

- Certification:

- CE, ISO9001, Nb/T 47003.1-2009,GB150-2011

- Applicable Industries:

- Manufacturing Plant, Food & Beverage Factory

- Core Components:

- Motor, Pump

- Warranty of Core Components:

- 1 Year

Basic Info.

| Material | SS304, SS316 | Application Fields | Vegetable Processing Plant, Meat Processing Plants |

| Scope of Application | Candy,Pastry,Drink,Candied,Fruit,Jam,Brew,Wine | Manufacturing Process | Stainless Steel Materials |

| Nominal Pressure | ATM~1.0MPa | Surface Treatment | Electrical Polish,Mirror Polish,Sand Polish |

| Production Capacity | 200 Set/Sets Per Month | Transport Package | Plywood Case |

Product Description

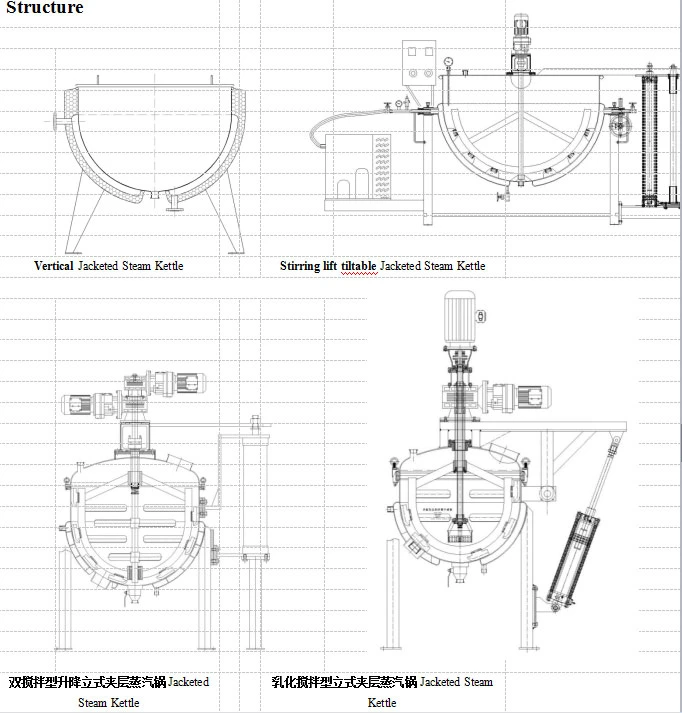

Feature

• Volume:50L~500L and multiple specification, also can design and manufacture according to customers'

requirement.

• The double structure of Kettle body is consists of inside and outside spherical kettle body, pass the steam or

conduction oil through the jacket as medium to heat.

• The connection adopts Tri-clamp, the tanks' inner use 304 or 316L. The inner surface mirror polishing

Ra≤0.28μm~0.6μm, outer surface can polishing, wire drawing and sandblasting according to customers'

requirement.

Application

• Applied to the processing of all kinds of food, also can be used in large restaurant or dining room to boil

soup, cook, stew, boil congee, etc.

• Used in liquid configuration, decoction and concentration in pharmaceutical, food, chemical industry and light

industry.

Design Parameter

Design pressure:Barrel according to customers' requirement(0.02MPa~0.8MPa)

Jacket according to customers' requirement(0.02MPa~0.5MPa)

Design temperature:Barrel and Jacket according to customers' requirement(0ºC~160ºC)

Surface Finish

Finish Type:Mechanical polishing, electrolytic polishing,sand blasting, pickling

Polishing precision:Inner wall 0.4μm,Outer wall 0.6μm

Material

Kettle Liner:304,316L

Kettle outer layer:304

Feet:304

Connection

In-outlet:In-outlet