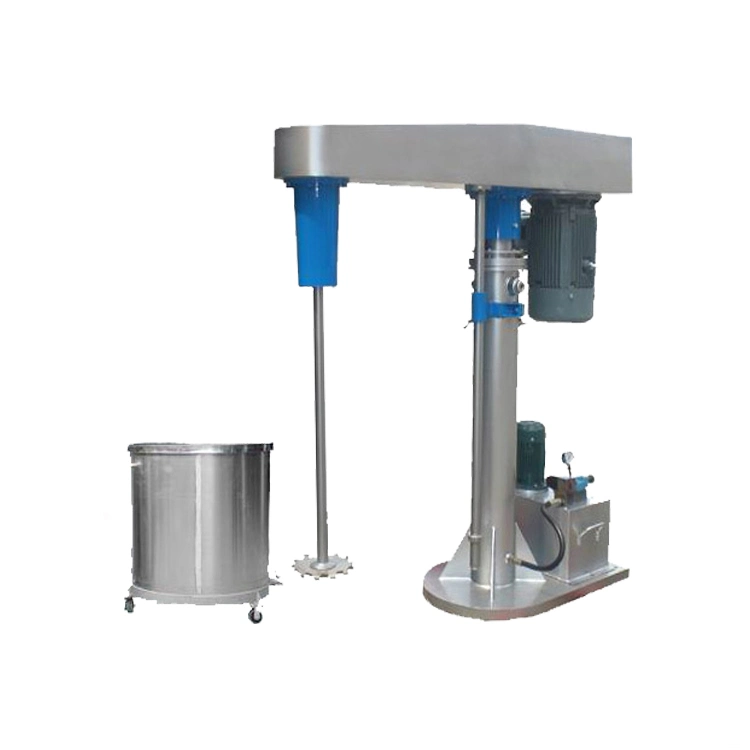

Liquid Coating/Paint Production/Making High Speed Double Cone Mixer/Container Mixer for Paint/ Paint Disperser

- After-sales Service:

- Network Support

- Warranty:

- 1year

- Mixer Type:

- High-Speed Disperser

Basic Info.

| Stirring Type | Spiral | Working | High Speed Mixer |

| Certification | CE, ISO | Application | Liquid with Suspended Solids, Viscous Fluid, Liquid |

| Layout Type | Verticle | Application Area | Chemical |

| Additional Capabilities | Milling, Coating | Mixing Drum Shape | Circular Groove |

| Condition | New | Operating type | Continuous Operating |

| Heating Way | Oil Electric | Power | Customizable |

| Warranty Period | 1year | Material | SS304 |

| Specification | 50L~3000L | Transport Package | Customizable |

| Production Capacity | 50picecs/Year | HS Code | 8474390000 |

Packaging & Delivery

| Package Size | 5000.00cm * 5000.00cm * 5000.00cm |

| Package Gross Weight | 68.000kg |

| Lead Time | 45 days (1 - 1 Sets) To be negotiated ( > 1 Sets) |

Product Description

Production process

The equipment can independently complete the dispersing and grinding, refining, cooling, filtering, vacuum suction, semi automatic filling the whole process, greatly reduce the labor intensity, the production time is the traditional equipment consuming 1 / 5, shortening the processing time, and easy cleaning. The utility model can be operated in a vacuum state, with no bubble production, no dust flying, and the quality of products is greatly improved.

Introduction

1)Pulp part:

The solvent through the liquid metering device is added to the liquid material groove, by vacuum suction to emulsifying kettle, start low speed anchor mixer, the powder material is sucked into the vacuum emulsifying tank for continuous stirred 10 minutes, then turn on the two sets of vertical high shear emulsifying 10 minutes, finally use horizontal emulsion machine, continuous cycle 30 minutes, finished slurry. A high shear inside the tank and an emulsion pump outside the tank are also used,

Ensure further refinement of materials, and greatly shorten the operation time.

2)paint part:

By vacuum, resin, film-forming agent from the liquid tank into the low-speed stirred tank, slurry through the bag filter is sucked into the low-speed mixer, the emulsion or solvent, additives, slurry mixing, then adding additives (thickener), blending paint.

3)filter packing:

After a good tune paint, vacuum defoaming after 5 minutes, stirring was stopped by a bag filter coating to semi-automatic filling machine for packaging. When the coating material using a two bag filters, can be switched with each use, does not affect the filling speed.

| power(kw) | Lifting height(mm) | Spindle speed(r/min) | capacity(L) | diameter(mm) | weight(kg) |

| 15./2.2 | 900 | 0~1420 0~3000 |

50 | 150 | 300 |

| 3/4 | 900 | 100 | 200 | 550 | |

| 5.5 | 1000 | 150 | 250 | 800 | |

| 7.5 | 1000 | 300 | 250 | 850 | |

| 11 | 1000 | 700 | 300 | 950 | |

| 15 | 1200 | 1000 | 300 | 1000 | |

| 18.5 | 1200 | 1200 | 350 | 1200 | |

| 22 | 1200 | 1500 | 350 | 1300 | |

| 30 | 1400 | 1800 | 400 | 1500 | |

| 37 | 1400 | 2200 | 450 | 1500 | |

| 55 | 1600 | 3000 | 500 | 1800 |