Glue High Speed Disperser Liquid and Powder Chemical Materials Mixing Machine

- After-sales Service:

- 12 Months

- Warranty:

- 12 Months

- Mixer Type:

- Homogenizer

Basic Info.

| Stirring Type | Diving | Working | High Speed Mixer |

| Certification | CE, ISO, API, SGS | Application | Liquid with Suspended Solids, Viscous Fluid, Liquid, Ink, Resin, Pigment |

| Layout Type | Verticle | Application Area | Chemical |

| Additional Capabilities | Milling, Drying, Granulating, Coating | Mixing Drum Shape | Disc |

| Condition | New | Operating type | Continuous Operating |

| Capacity | 100-300L | Power | 7.5kw |

| Key Selling Points | Competitive Price | Stroke | 800mm |

| Video Outgoing-Inspection | Provided | Core Components | Motor |

| Voltage | Customer Required | Range of Spindle Speed(r.p.m) | 1 - 1500 r.p.m |

| Stirring Method | Dispersion Disc | Dimension(L*W*H) | According to The Prduct′s Model |

| Packaging Details | Suitable Delivery and Protect The Machine | Function | Mixing, Dispersing |

| Specification | 10-5000L | Transport Package | Wood Case |

| Production Capacity | 50 Sets | HS Code | 8479820090 |

Packaging & Delivery

| Package Size | 400.00cm * 120.00cm * 210.00cm |

| Package Gross Weight | 800.000kg |

Product Description

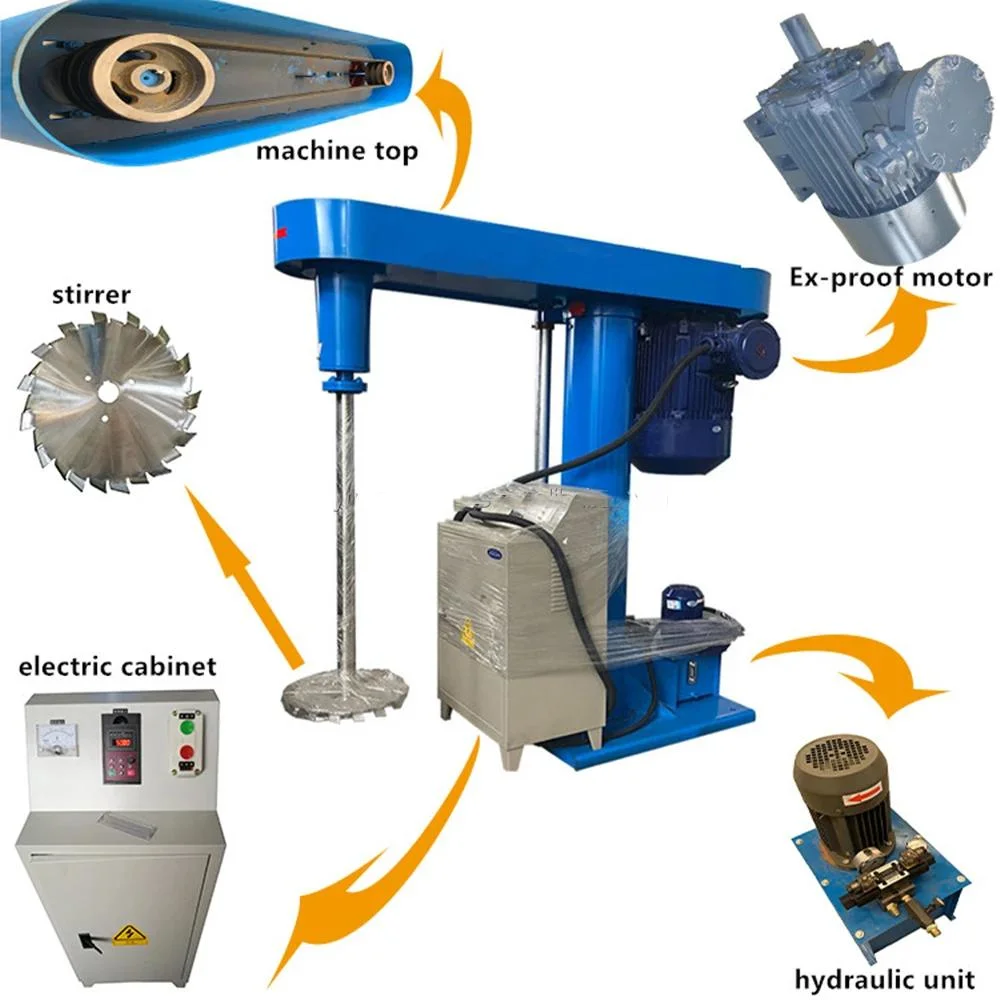

High speed lifting and dispersing machine is an efficient equipment for mixing, dispersing, blending and dissolving various mixed liquids and solids. The main motor is a speed-regulating motor with a speed-regulating range of 80-1600 RPM. The principle of high speed lifting and dispersing machine is composed of four parts: hydraulic lifting, mixing system, transmission and electrical apparatus. According to the requirements of users, a machine can be equipped with more than one cylinder, alternate use.

Working principle

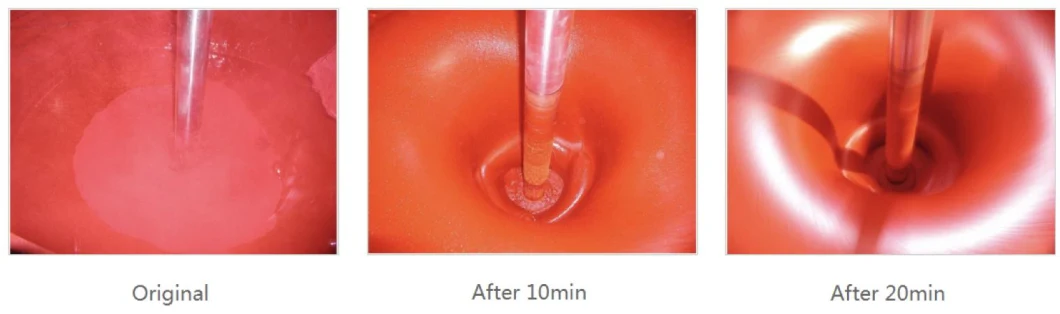

Through the high-speed rotation dispersing disc, the material will become in annular form flow, resulting in strong vortex flow, which descend down to the bottom of the vortex in spiral state. During the process, materials are dispersed, dissolved, mixed and emulsified efficiently due to the strong shearing crash and friction among the particles.

Feature

Rapid dispersion of solids, powders, prills and pigments;

Consistent, repeatable particle size and distribution;

Easy clean, hygienic construction;

Extensive optional blade profiles;

Low wear, low maintenance;

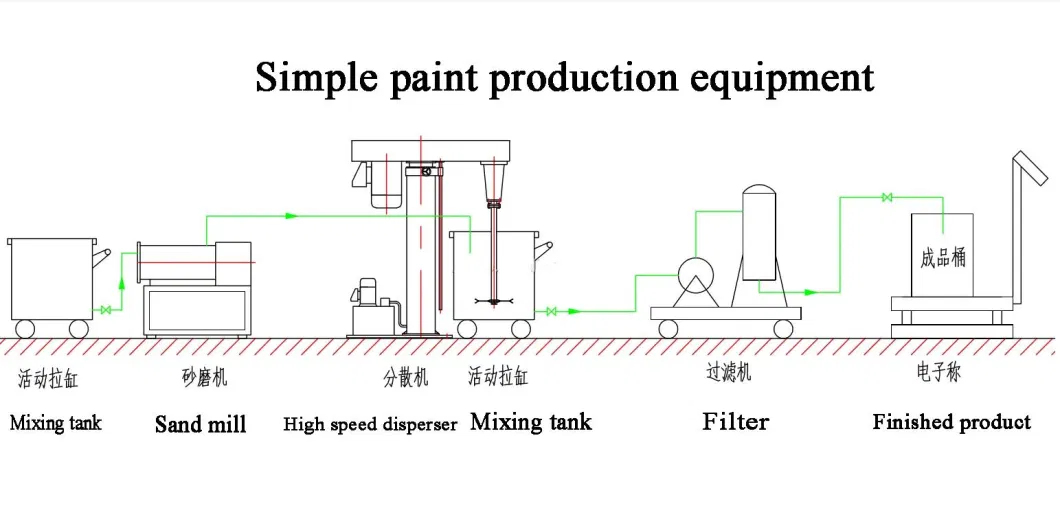

Flow Chart

Application

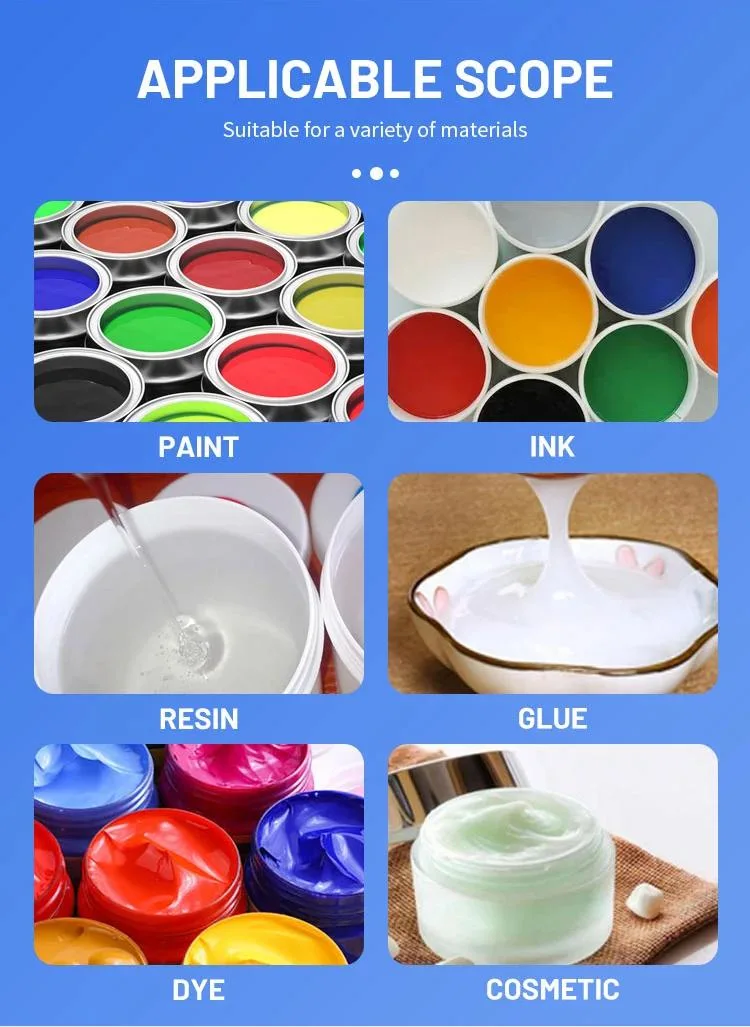

Coating: Water-based coating, Solvent-based coating, Decorative coating, Latex paint;

Paint: Car paint, Finish paint, Wood painting, Industrial paint;

Ink: Gravure printing ink, flexographic ink, offset printing ink, silk screen ink, UV light solid ink, digital inkjet ink, etc;

Pigment: Dye, color painted pigment, pen liquid, watercolor;

Electronic Materials: Battery diaphragm alumina, lithium iron phosphate, ceramic slurry, flame retardant;

Food Industry: chocolate syrup, paste, etc.

Product Parameters

| Power (KW) | Capacity (L) | Disc Diam(mm) | Speed (rpm) | Stroke (mm) | Hydraulic Power (kW) |

| 2.2 | 50-100 | 150 | 0-1440 | 600 | 0.75 |

| 4 | 50-200 | 200 | 0-1440 | 600 | 0.75 |

| 5.5 | 80-250 | 200 | 0-1440 | 800 | 0.75 |

| 7.5 | 100-300 | 250 | 0-1440 | 800 | 0.75 |

| 11 | 100-400 | 250 | 0-1440 | 800 | 0.75 |

| 15 | 150-500 | 300 | 0-1440 | 800 | 0.75 |

| 18.5 | 200-800 | 300 | 0-1440 | 1100 | 1.1 |

| 22 | 200-1000 | 300 | 0-1440 | 1100 | 1.1 |

| 30 | 300-1500 | 350 | 0-1440 | 1100 | 1.1 |

| 37 | 400-2000 | 400 | 0-1440 | 1100 | 1.5 |

| 45 | 500-2500 | 450 | 0-1440 | 1100 | 1.5 |

| 55 | 600-3000 | 450 | 0-1440 | 1300 | 2.2 |