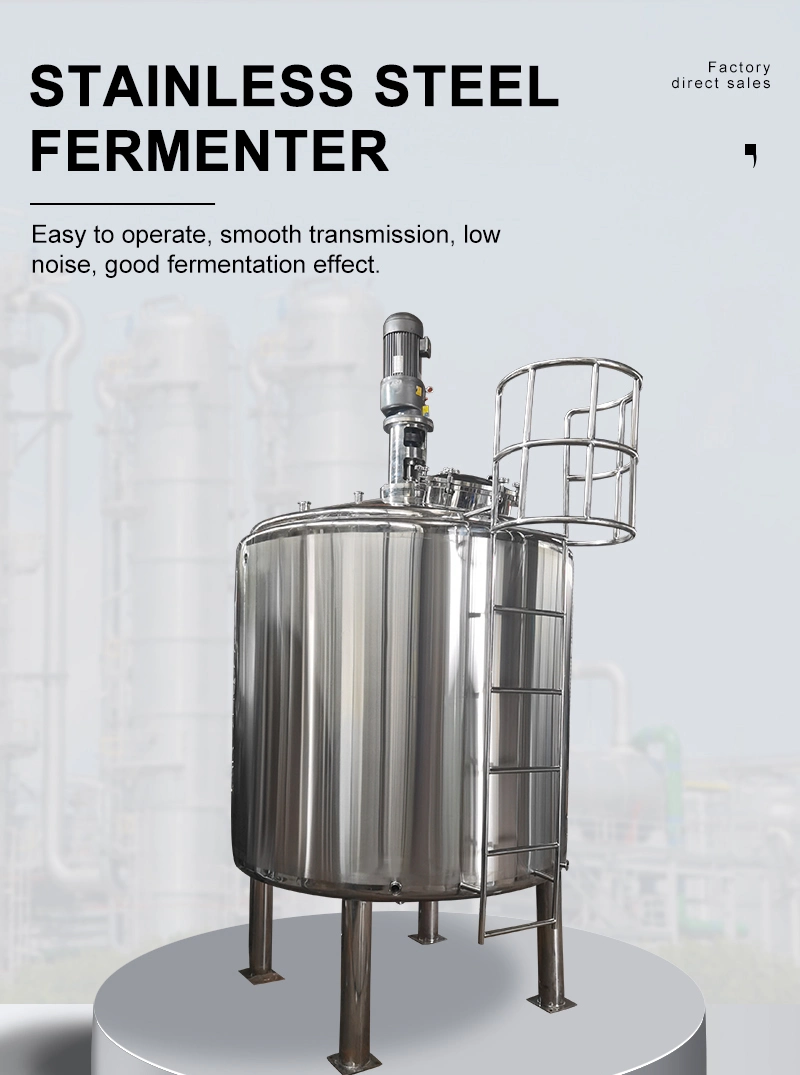

3000L Escalator Mixed Milk/Dairy Products/Beverage Fermentation Tank

- After-sales Service:

- Online Support

- Warranty:

- 1 Year

- Certification:

- ISO9001

- Process:

- Ferment

- Power Source:

- Gas

- Automatic Grade:

- Automatic

Basic Info.

| Customized | Customized | Application | Yogurt |

| Motor Power | 3kw | Seal Form | Mechanical Seals |

| Cylinder Diameter | 1500mm | Motor Speed | 24rpm |

| Material | SUS304 | Cylinder Thickness | 4mm |

| Structure | Vertical | Product Usage | Fermentation |

| Type | Fermentation Tank | Warranty Period | 1 Year |

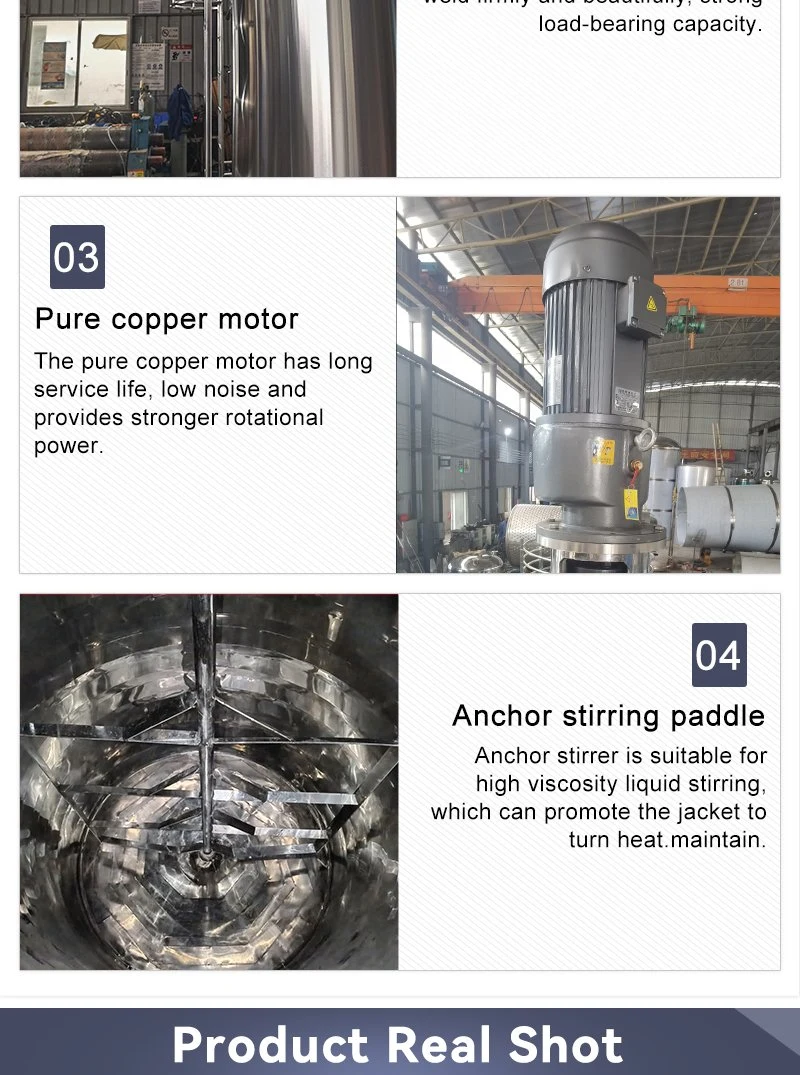

| Stirring Paddle | Anchor Type Stirring Paddle | Jacket | Three Layers with Jacket |

| Specification | 3000L | Transport Package | Wooden Case |

Product Overview

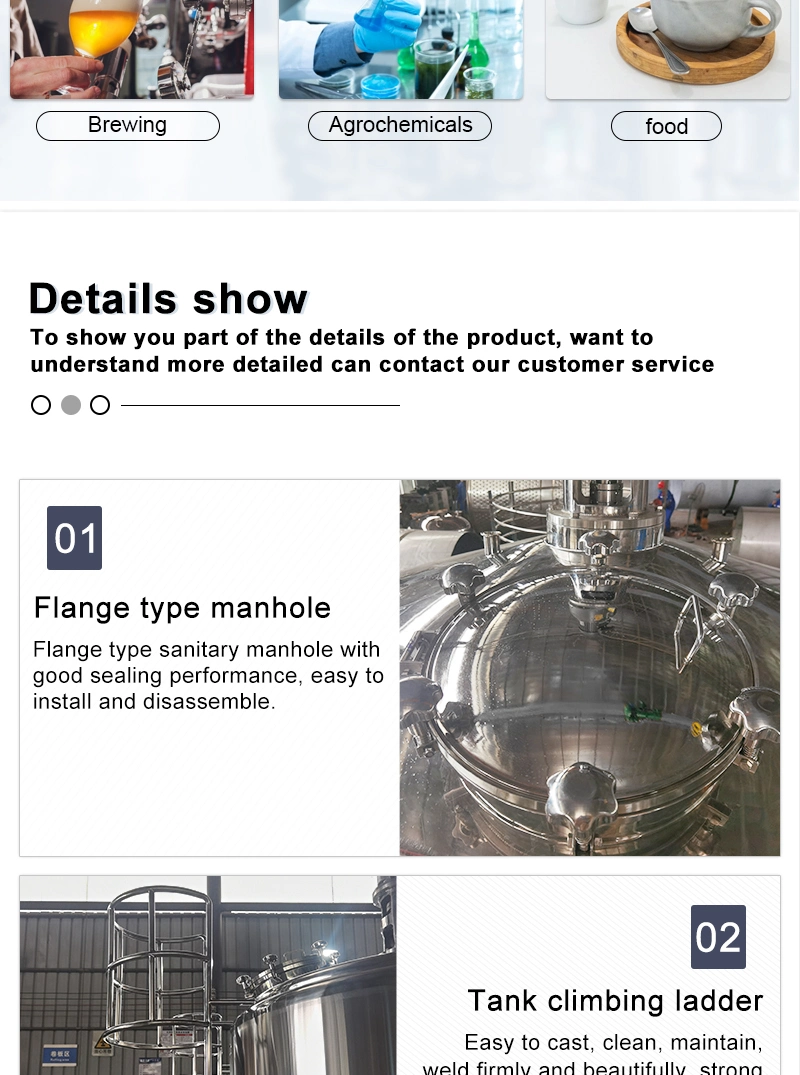

Fermentation tank is a common fermentation equipment in food, chemical, biological and pharmaceutical industries, which is applicable to the fermentation of various microorganisms. The tank body of fermentation tank is equipped with sandwich and insulation layer, which can be heated, cooled and insulated.

Product features

The fermentation tank is mainly composed of three parts: fermentation tank, fermentation control system and piping system. There are stirring paddles in the tank for continuous stirring during the fermentation process, and control sensors on the top plate of the tank, most commonly pH electrodes and DO electrodes, which are used to monitor the pH and DO changes of the fermentation solution during the fermentation process, and the controller is used to display and control the fermentation conditions.

Fermentation tanks smaller than 10L are made of pressure-resistant glass and can be autoclaved; those above 10L are made of stainless steel and equipped with an online sterilization system. In order to increase the amount of dissolved oxygen when culturing bacteria, high rotational speed is usually used, and the height-to-diameter ratio is usually 2.5~3.0, so the tanks used for culturing bacteria and other microorganisms are usually thin and long. The parameter control system mainly consists of rotational speed control, temperature control, pH control, dissolved oxygen control, and liquid level control.

Function description

1.Temperature control:Digital setting, PT-100 temperature probe, steam/electric heating and cooling water automatic temperature control.

2.pH control:Peristaltic pump automatically adds alkali or acid for regulation. Imported pH electrode can be sterilized by high temperature steam.

3.DO control:Range 0-100% or 0-200%; Imported DO electrode, optional linkage control with speed and ventilation.

Technical parameter

| Volume(L) | Cylinder Size(mm) | Motor Power(KW) | Speed(rpm) | Material |

| 50 | 300 | 0.75 | 50-500 | SUS304 / SUS316L |

| 100 | 500 | 0.75 | 50-500 | SUS304 / SUS316L |

| 200 | 600 | 1.1 | 50-500 | SUS304 / SUS316L |

| 300 | 700 | 1.5 | 50-500 | SUS304 / SUS316L |

| 500 | 900 | 2.2 | 50-500 | SUS304 / SUS316L |

| 800 | 1000 | 3 | 50-500 | SUS304 / SUS316L |

| 1000 | 1100 | 4 | 50-500 | SUS304 / SUS316L |

| 2000 | 1300 | 5.5 | 50-500 | SUS304 / SUS316L |

| 3000 | 1500 | 7.5 | 50-500 | SUS304 / SUS316L |

| 4000 | 1700 | 7.5 | 50-500 | SUS304 / SUS316L |

| 5000 | 1900 | 11 | 50-500 | SUS304 / SUS316L |

| 10000 | 2000 | 15 | 50-500 | SUS304 / SUS316L |

Note: The technical parameters of the Fermentation tank in the table are standard parameters, which are only for reference. We can design customized solutions according to customer needs.