PRODUCT PARAMETERS

| Model No. | Motor Power(KW) | Speed(RPM) | Flow Rate(m3/h) | Outlet Pressure (Bar) | Suction Capacity(g/s) |

| SRH-C-120 | 5.5/7.5 | 2900 | 0-10 | 1.5 | 0-500 |

| SRH-C-140 | 11/15 | 2900 | 0-20 | 2 | 0-1000 |

| SRH-C-165 | 22/30 | 2900 | 0-30 | 2.5 | 0-2000 |

| SRH-C-200 | 37/45 | 2900 | 0-50 | 3 | 0-3000 |

| SRH-C-260 | 55/75 | 2900 | 0-70 | 4 | 0-4000 |

Notice:

* The flow range data in the above table is test result based on water as test media.

* The suction capacity depends on the characteristics of the powder itself (such as particle size,swellability, fluidity, etc.). If it cannot be confirmed, please provide samples or select by experimental data;

* If there are special working conditions, please provide detailed and accurate technical parameters and process requirements for our professional engineers to provide corresponding solutions.

* The data in this form is subject to change without prior notice. The correct parameters are subject to the actual product provided.

PRODUCT DESCRIPTION

All the process steps can be completed with only one device: after the powder suction tube is fed, it can quickly complete the powdering, feeding, wetting, and dispersion without agglomeration. Not only can the powder be wetted, but it can also be dispersed into the liquid in a vacuum environment to avoid a large amount of air entering. It can avoid material agglomeration, achieve good reaction effect, higher material utilization rate and better product quality. The device's high module integration saves a lot of piping and process steps, minimizing production costs.

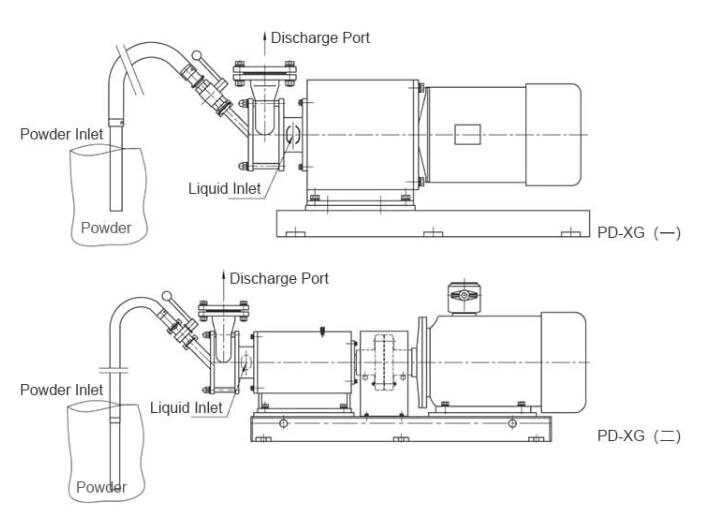

Working Principle

The device has a special rotor, which rotates at high speed to generate vacuum. The powder is evenly sucked into the working chamber through the suction pipe, and is evenly distributed in the fast flowing liquid flow. In the liquid flow, the powder is completely wetted instantaneously, and no generation occurs.The agglomerate mass does not form a crust on the surface of the liquid stream, the stirring shaft and the wall of the container, avoiding the hard crust which is easy to occur in the conventional process.Therefore, the equipment can greatly improve the quality of the product, and can also eliminate the auxiliary facilities necessary in the conventional treatment process.