PRODUCT PARAMETERS

| Model No. | Motor Power(kw) | Motor Speed(r/min) | Flow Range(m3/h) | Inlet | Outlet |

| SRH-1-60 | 1.1 | 2900 | 0-1 | DN40 | DN32 |

| SRH-1-80 | 1.5 | 0-1.5 | DN40 | DN32 | |

| SRH-1-100 | 2.2 | 0-3 | DN40 | DN32 | |

| SRH-1-130 | 4 | 0-4 | DN40 | DN32 | |

| SRH-1-140 | 5.5 | 0-5 | DN50 | DN40 | |

| SRH-1-165 | 7.5 | 0-8 | DN50 | DN40 | |

| SRH-1-180 | 11 | 0-12 | DN65 | DN50 | |

| SRH-1-190 | 15 | 0-20 | DN65 | DN50 | |

| SRH-1-200 | 22 | 0-25 | DN65 | DN50 | |

| SRH-1-210 | 30 | 0-35 | DN80 | DN65 | |

| SRH-1-230 | 45 | 0-50 | DN100 | DN80 | |

| SRH-1-245 | 55 | 0-75 | DN100 | DN80 | |

| SRH-1-260 | 75 | 0-90 | DN125 | DN100 | |

| SRH-1-275 | 90 | 0-100 | DN125 | DN100 | |

| SRH-1-280 | 132 | 0-130 | DN125 | DN100 |

*The above information is for reference only and can be customized according to customer requirements.

*This equipment can be customized according to the nature of raw materials to meet the needs of theprocess, such as greater viscosity, homogenization and other requirements.

PRODUCT STRUCTURE

The emulsification pump (also called in-line high-shear dispersion mixer) is a high-efficient fine mixing equipment which integrates mixing, dispersion, crushing, dissolution, fine, depolymerizing,homogenization and emulsification, whose working components are mainly stator and rotator. The rotor rotates rapidly to produce centrifugal force and hydraulic force and the stator remains stationary.Through the precise combination of the rotor and the stator, a strong shear force is generated during high-speed rotation, and the material is subjected to strong shear, centrifugal extrusion, impact rupture,liquid friction, and uniform turbulence. Thus, various media such as immiscible solid phase, liquid phase,and gas phase are uniformly and finely dispersed and emulsifed in an instant. After a reciprocating cycle, a stable and high-quality product is finally obtained.

WORKING PRINCIPLE

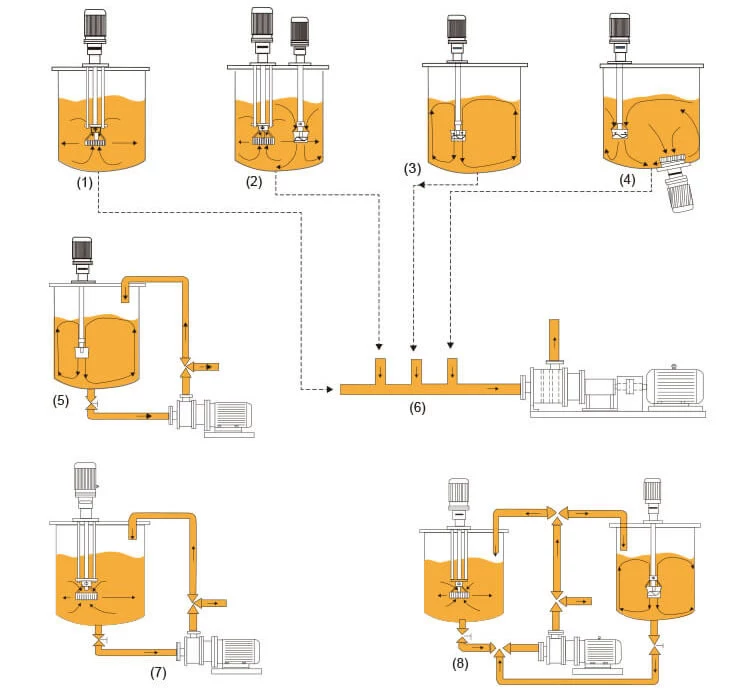

The emulsification pump/in-line high-shear dispersion mixer can efficiently, quickly, and evenly distribute one or more phases into another continuous phase, while in the usual case the phases are mutually insoluble. By high shear linear velocity generated by high-speed rotation of rotor and high kinetic energy brought by high-frequency mechanical effect, the material in the narrow gap of rotor and stator is forced by a strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction,impact tear and turbulence and other comprehensive effects. That makes incompatible solid phase,liquid phase and gas phase instantly homogenized, dispersed and emulsified under combined action of corresponding mature technology and proper amount of additives. Fnally stable and high-quality products are available after repeated cycles of high-frequency.

Three groups of stator and rotor are installed in the working chamber of the emulsification pump. The transmission shaft in the working chamber is cantilevered. The elastic coupling connects the motor and the spindle in the bearing housing to improve the operating quality of the transmission shaft. The sealing forms are optional based on different work conditions. It is suitable for medium and large batches of on-line continuous production or recycling processing production.